Scale automation by upgrading manual tasks and existing robot stations

Upgrade existing robots in minutes and power new stations for fast, flexible automation, on stationary or moving lines.

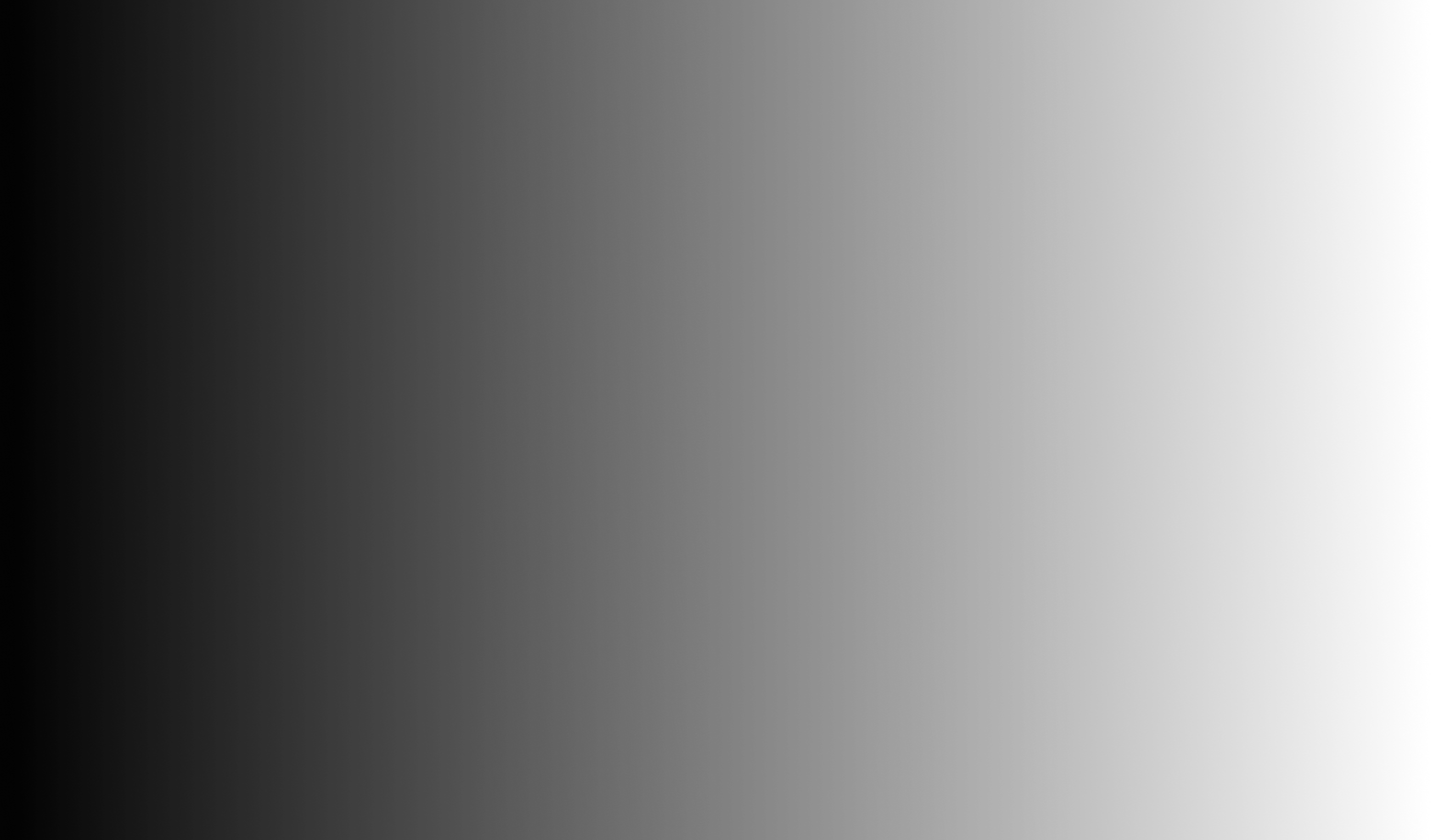

Make existing robots smarter

Transform your current robots into vision-guided problem-solvers. Inbolt installs quickly, trains from a CAD model, and runs in minutes, reducing downtime, improving cycle time and extending the life of automation assets.

24 hours

For full deployment

6 months

ROI payback period

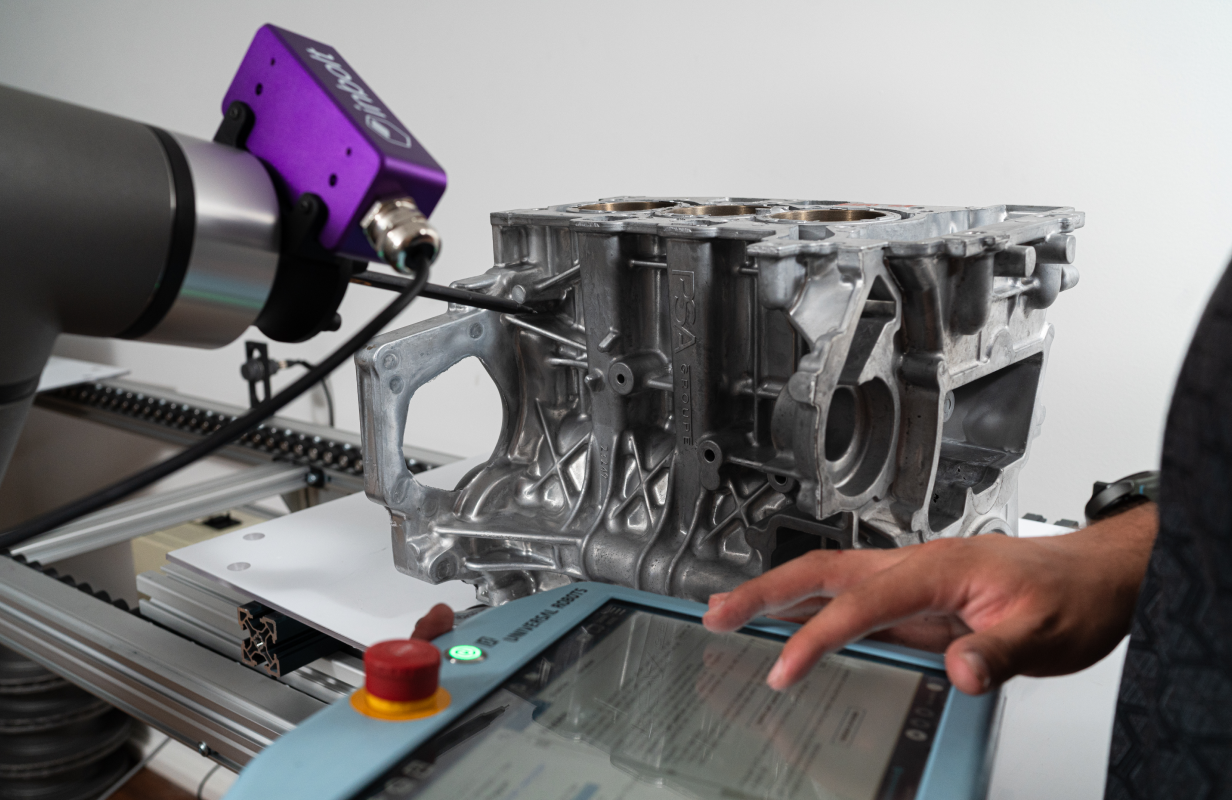

Automate new workstations

Every new robot can start smarter with Inbolt pre-installed. Our hardware-agnostic system integrates seamlessly, enabling real-time adaptability to scale automation across your factory from day one.

100%

Compatible with any robot & station

10x

Faster commissioning

Proven impact, measurable results

5

5 mins

Training time

80

80 ms

Perception to motion

70

70 +

Factories using Inbolt

40

40 M

Robot cycles powered in 2025

Vision-guided automation for every task

From picking to fastening, Inbolt adapts to diverse manufacturing processes — static or moving — with unmatched precision.

Bin Picking

Pick & Place and De-racking

Fastening

Trusted by the world’s top manufacturers

Ready to bring intelligence to your robots?

Let’s discuss how Inbolt can retrofit your robots or power new stations for faster, smarter automation, deploying quickly to boost productivity and performance.