Want to Sound Smart About Vision‑Guidance for Robots?

Whether you’re new to the topic or looking to deepen your knowledge, here are 11 key terms every manufacturing and automation professional should know.

1. Computer Vision

Technology that enables computers to “see” and interpret images or video from cameras and sensors.

2. 3D Vision Sensors

Cameras or laser-based devices that capture spatial data to create a detailed three‑dimensional view of objects or environments.

3. Workpiece

The part or object a robot is working on, whether that’s picking, placing, welding, or inspecting it.

4. CAD‑to‑Path

Using a 3D design (CAD model) of a part and automatically generating the movement path a robot needs to follow to work on it (like applying glue) without having to manually program every step.

5. Part Localization

Determining the exact position and orientation of a part so a robot can interact with it accurately.

6. Point Cloud

A dense set of points in three‑dimensional space representing the surface of an object, often used for measurement and guidance.

7. Sim2Real

Teaching a robot something in a virtual world (a simulator) and then making it work the same way in the real world, even though real life is messier and less predictable.

8. Real2Sim

Using data from the real world to make virtual simulations more accurate. This helps simulations better match reality, so robots or AI can train in a virtual world that feels more like the real one.

9. Adaptive Path Planning

Adjusting the robot’s trajectory mid‑task based on vision feedback to handle variations or misalignments.

10. Visual Servoing

A feedback control method where the robot’s movement is continuously adjusted using live camera data.

11. Edge AI Processing

Running computer vision algorithms directly on local devices, like smart cameras or embedded processors, to reduce delays and reliance on cloud computing.

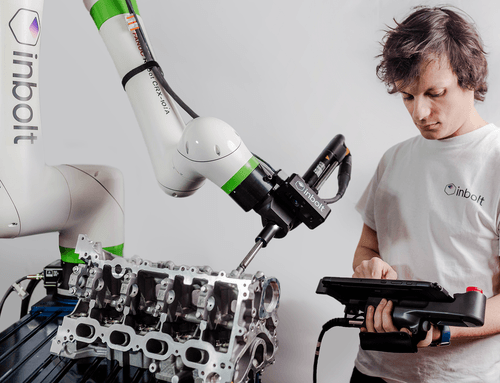

Learn how Inbolt’s Vision-Guidance can enhance the flexibility of your automation, reducing downtime and cutting costs. Click here to book a demo.

Explore more from Inbolt

Access similar articles, use cases, and resources to see how Inbolt drives intelligent automation worldwide.

Why the future of automation is being written by the automotive industry

Reliable 3D Tracking in Any Lighting Condition

The Circular Factory - How Physical AI Is Enabling Sustainable Manufacturing

NVIDIA & UR join forces with Inbolt for intelligent automation

KUKA robots just got eyes: Inbolt integration is here

Albane Dersy named one of “10 women shaping the future of robotics in 2025”

Inbolt Joins NVIDIA Inception to Accelerate AI-Driven Automation