Proven impact, measurable results

30

30 %

Faster cycle times

5

< 5 mins

Training time

70

70 +

Factories using Inbolt

20

20 M

Robot cycles powered in H1 2025

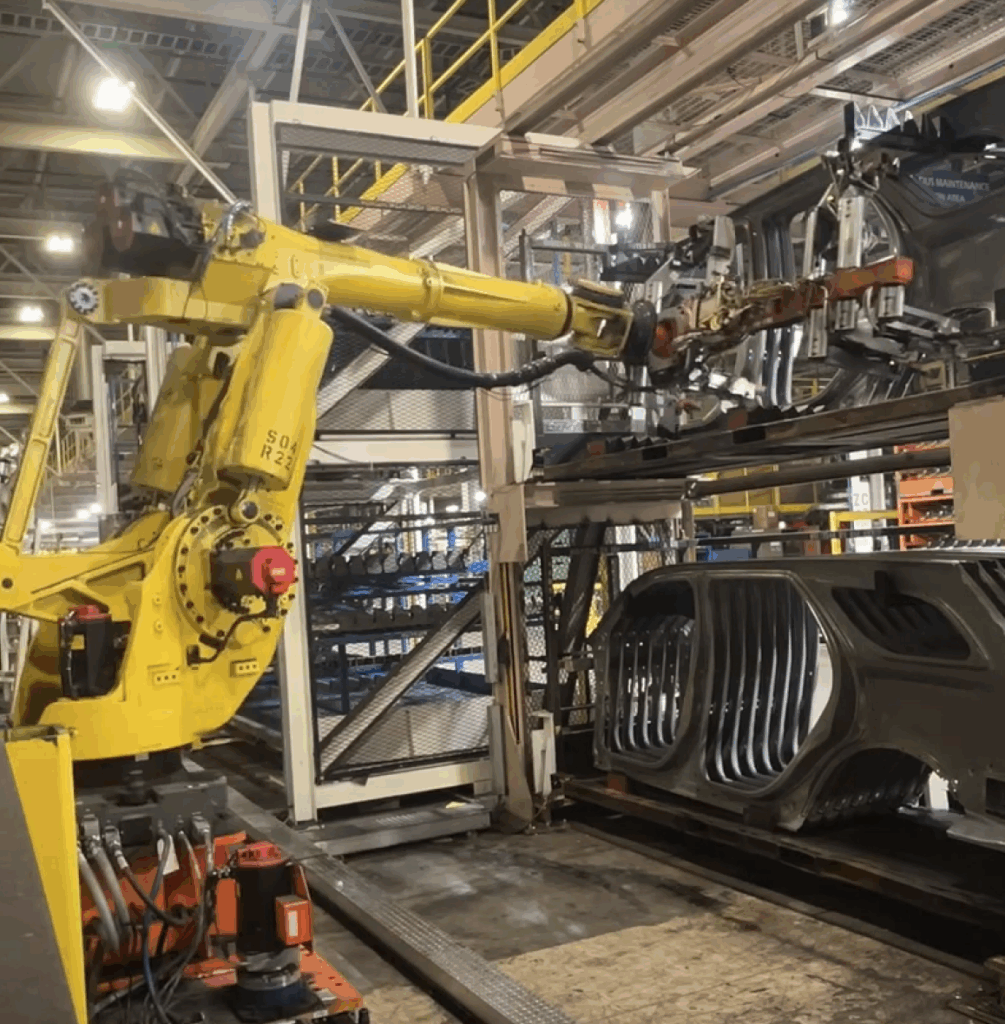

Why automate placement & de-racking with Inbolt

Reduce cycle times, avoid collisions, and keep production running reliably.

Maximize uptime

Real-time localization eliminates mispicks and collisions. Keep robots running even with misaligned racks or manual loading variability.

Faster cycles, higher throughput

Skip slow scanning. Inbolt pinpoints part position instantly, cutting cycle time by up to 30% and increasing station productivity.

Rapid ROI

Retrofit existing robots in hours and achieve payback in as little as 3 months, with no need for mechanical rework.

Technology built for precision placement

Advanced vision-guidance to keep pick-and-place operations reliable and repeatable.

Robot-mounted vision

One camera per robot for higher accuracy and flexibility without costly overhead setups.

Real-time trajectory updates

Continuously recalculates pick paths for perfect alignment on every cycle.

Optional safety zone protection

Automatically stops the robot when parts are outside safe picking positions.

CAD-based training

Deploy in days using only a CAD model, no time-consuming data collection needed.

Lighting agnostic

Performs in variable lighting without controlled environments or extra equipment.

Seamless integration in robot logic

Integrate the Inbolt driver in your existing robot program without heavy modifications.

Proven results in real factories

Zero gripper jams, saving Volkswagen 30 min per incident

FAQ

Everything you need to know about using Inbolt for placement and de-racking.

-

De-racking automation uses robots to unload parts from custom racks and position them for the next production step. Inbolt’s vision-guided system identifies each part’s position and orientation in real time, even if racks shift or parts are misaligned, ensuring precise and collision-free handling.

-

Our robot-mounted 3D camera and AI recalculate the pick trajectory in milliseconds based on the actual live position of the part. If a rack or part is too far out of tolerance, Inbolt’s safety zone triggers an abort mission signal, avoiding collisions and alerting an operator to adjust manually.

-

Yes. Inbolt retrofits existing robots quickly without mechanical rework. We’ve deployed retrofits in hours, achieving up to 97% downtime reduction and a 3-month ROI.

-

Customers typically see up to 30% faster cycle times compared to laser scanning or fixed vision systems. This leads to higher throughput and improved OEE across stations.

-

Yes. Inbolt is currently compatible with FANUC, ABB, Universal Robots, KUKA and Yaskawa. Our integration is hardware-agnostic, making it easy to standardize across your factory.

-

Most customers achieve ROI in 3–6 months thanks to reduced downtime, higher throughput, and elimination of costly fixture modifications.

Ready to automate placement & de-racking?

Our team can help you retrofit existing stations or launch new ones with precision vision-guidance. Deploy fast, boost uptime, and hit ROI targets sooner.

Explore more from Inbolt

Access articles, use cases, and resources to see how Inbolt drives intelligent automation worldwide.

30% Cycle Time Reduction in Automotive Pick & Place

Albane Dersy named one of “10 women shaping the future of robotics in 2025”

Eurazeo AI x Industry Workshop (Nov 26)

Inbolt Product Brochure