Automating Semi-structured bin picking

How to automate the picking of steering knuckles scattered in a bin?

Customer: Confidential

Location: Confidential

Challenge

Semi-structured bin picking applications account for more than 60% of such operations in the automotive industry. Fully unstructured bin storage, where parts are randomly placed, is only feasible when part damage is not a concern. However, when parts are processed, painted, or machined, they are typically stored in “semi-structured” environments to minimize damage. In these cases, parts are often arranged in layers next to each other, rather than cluttered.

Despite this more organized storage method, automating the unloading of these bins poses significant challenges:

- Inconsistent Dunnage Positioning: Most dunnage systems, typically pallets brought by forklifts, do not have repeatable, consistent positions at the station.

- Irregular Part Orientation: Parts within the bins are scattered and rotated unpredictably, requiring advanced vision systems to realign the robot’s trajectory for precise picking.

Solution

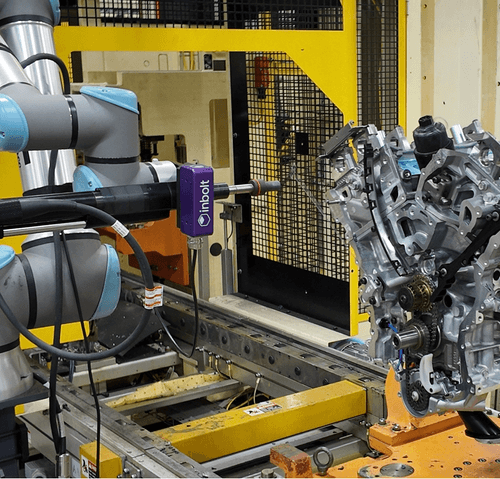

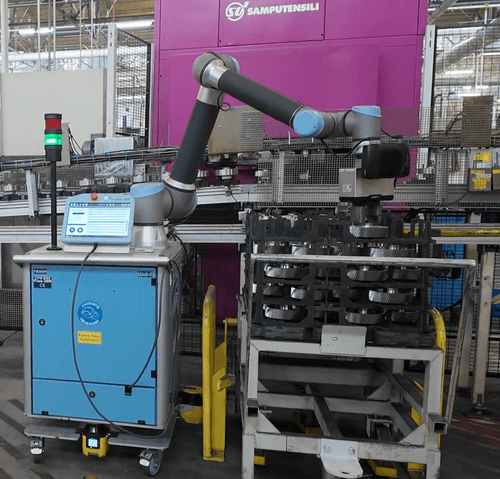

GuideNOW Real-time was selected to automate this task. A GuideNOW 3D camera was mounted on the End of Arm Tooling (EOAT) of an ABB cobot. With its advanced real-time localization capabilities, the system detected the position and orientation of the irregularly placed knuckles, adjusting the robot’s trajectory to pick and place them with high precision.

This solution enabled Beko to automate the bin-picking process without requiring expensive modifications to the dunnage system or logistics materials, significantly reducing material and integration costs.

Benefits

- Cost-Efficient Automation: No changes to the existing production environment were required, minimizing automation costs.

- High Precision: GuideNOW’s real-time 3D vision ensured accurate handling of parts, even in semi-structured environments.

- Flexibility: The system can quickly adapt to new part variants and irregular positions without complex reprogramming.

Explore more from Inbolt

Access similar articles, use cases, and resources to see how Inbolt drives intelligent automation worldwide.

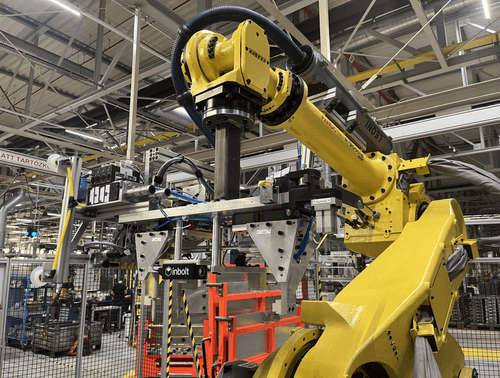

30% Cycle Time Reduction in Automotive Pick & Place

Stellantis Reduces Tightening Rejects by 90.5% with Inbolt’s Vision-Guidance at their Trenton Plant

Stellantis Valenciennes Cuts 2.7 Tons in Daily Handling with Inbolt’s Vision-Guided Automation

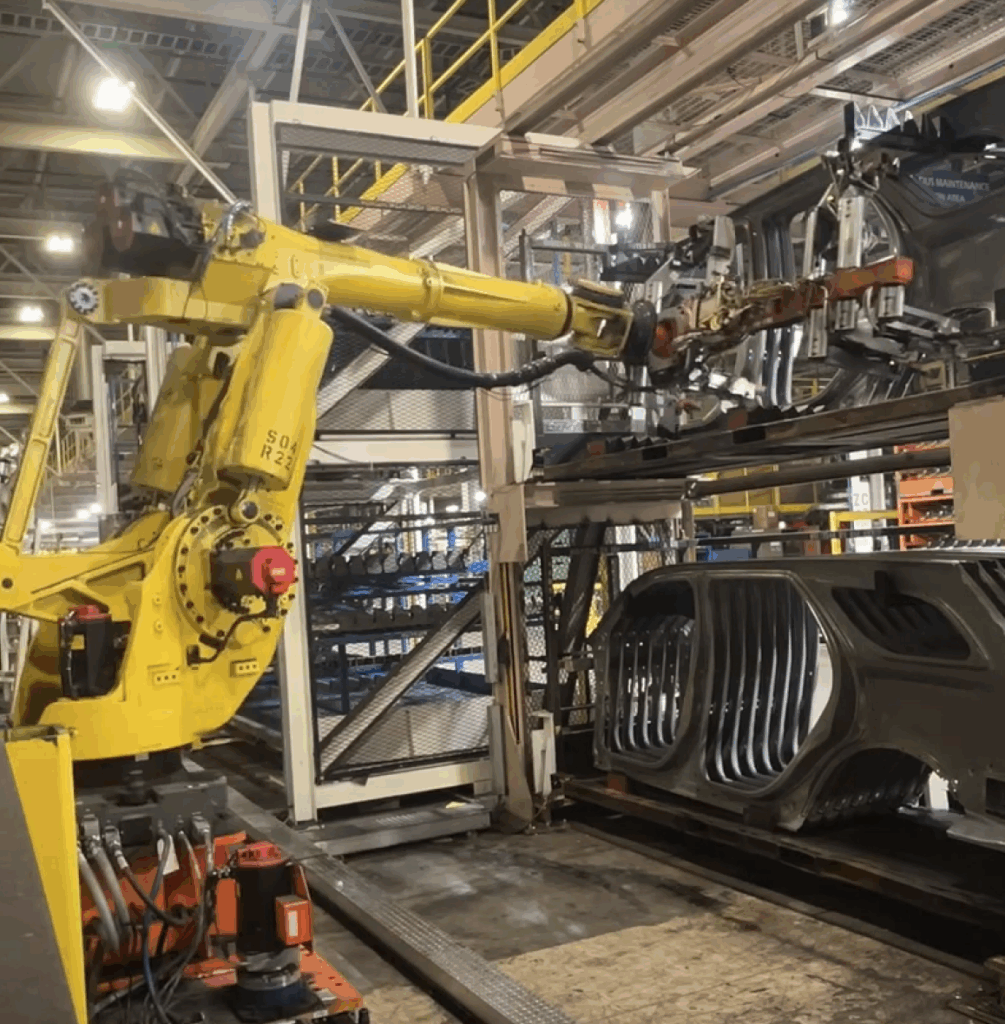

Stellantis Enhances Bodyshop Efficiency by 97% with Inbolt’s Vision-Guided De-Racking Solution

Stellantis automates semi-structured depalletizing with GuideNOW

Stellantis Automates Small Parts Pick and Place

Beko Automates Stones Picking from Bin & Precise Placing