Why add Inbolt to new stations

Build stations that are flexible, scalable, and ready to meet future production demands.

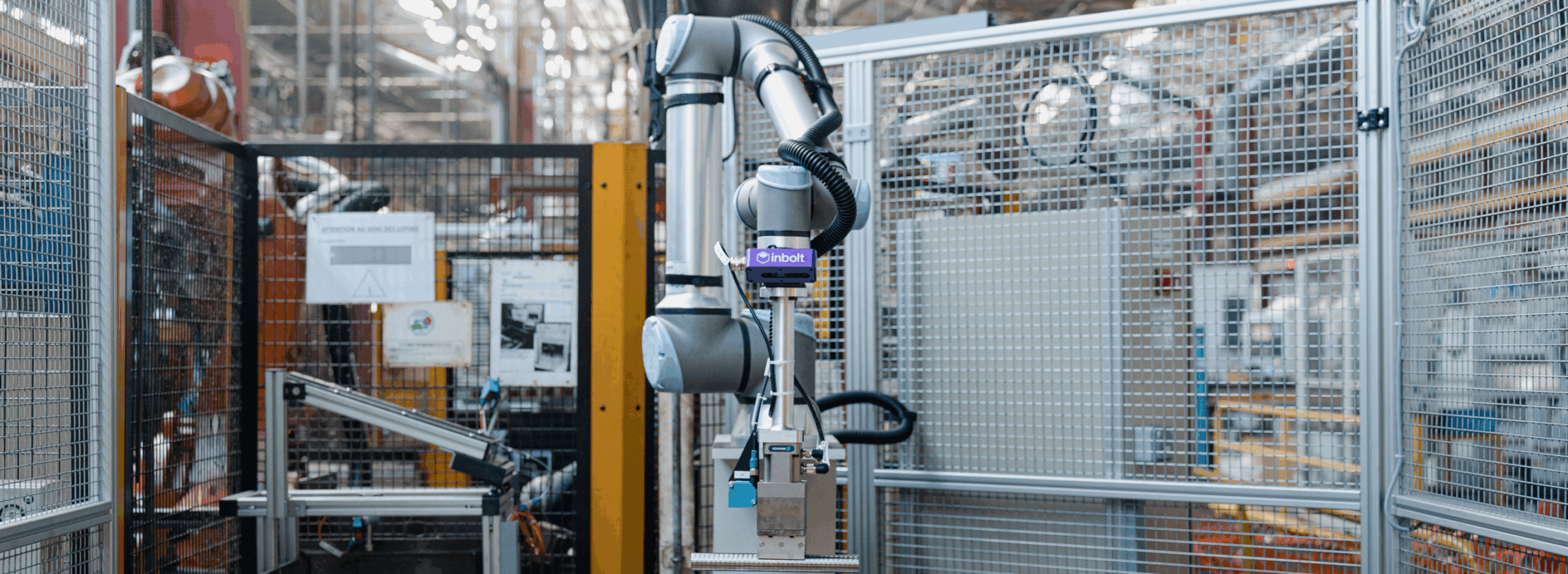

Future-ready automation

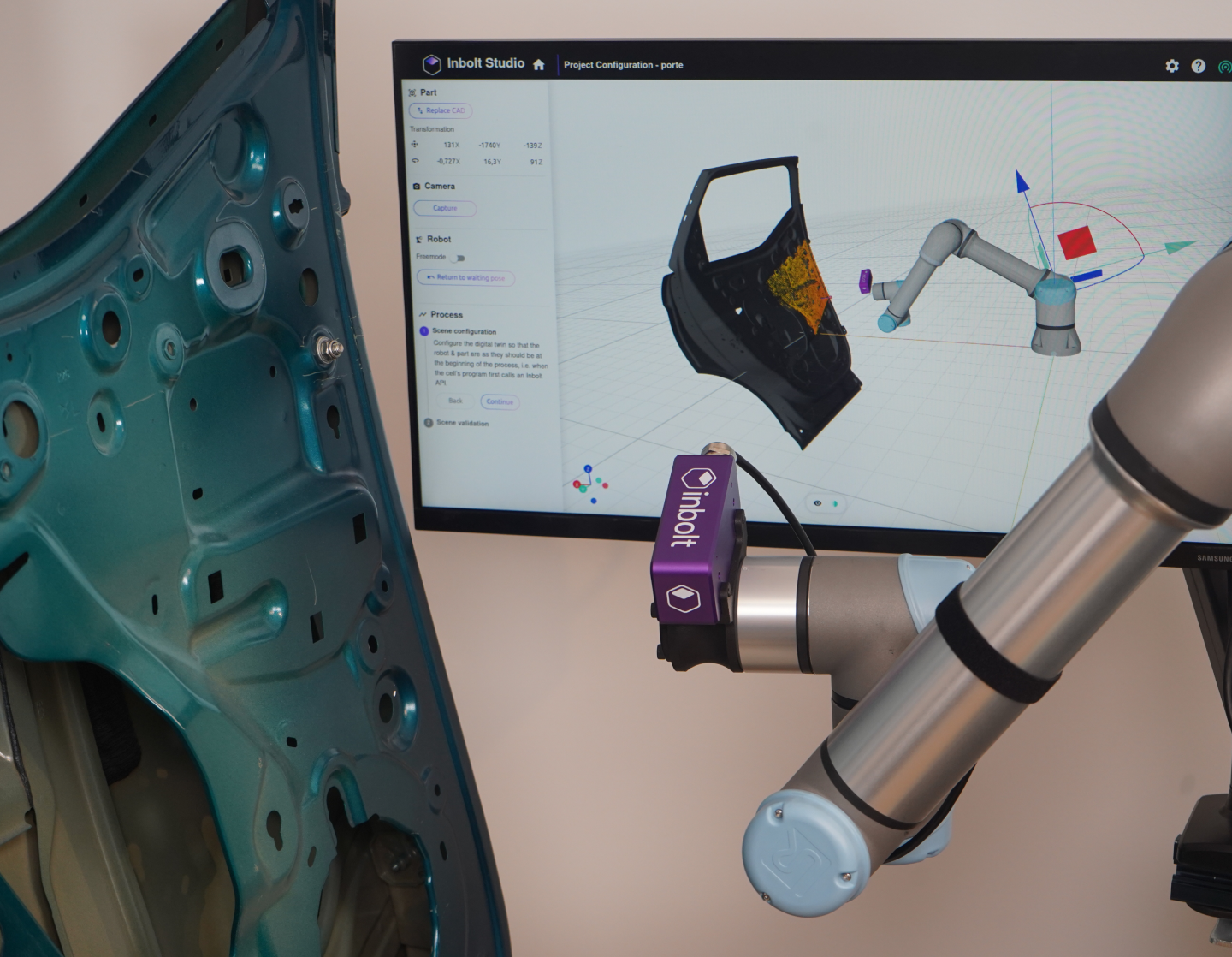

Equip your stations with vision-guided intelligence that adapts to new parts, variants, and layouts without heavy reprogramming.

Faster commissioning

Configure, train, and deploy in days with CAD-based setup, reducing engineering time and getting production running sooner.

Lower long-term costs

Reduce the need for custom jigs and fixtures, minimize future integration expenses, and maximize your ROI from day one.

Proven results in real factories

Flexible bin picking at Caen reduced downtime and sped up production.

Explore more from Inbolt

Access articles, use cases, and resources to see how Inbolt drives intelligent automation worldwide.

KUKA robots just got eyes: Inbolt integration is here

Stellantis Enhances Bodyshop Efficiency by 97% with Inbolt’s Vision-Guided De-Racking Solution

American Automotive Summit (Oct 21-22)

Ready for every industry’s next station

Inbolt works wherever your next station is — from automotive to electronics and home goods.

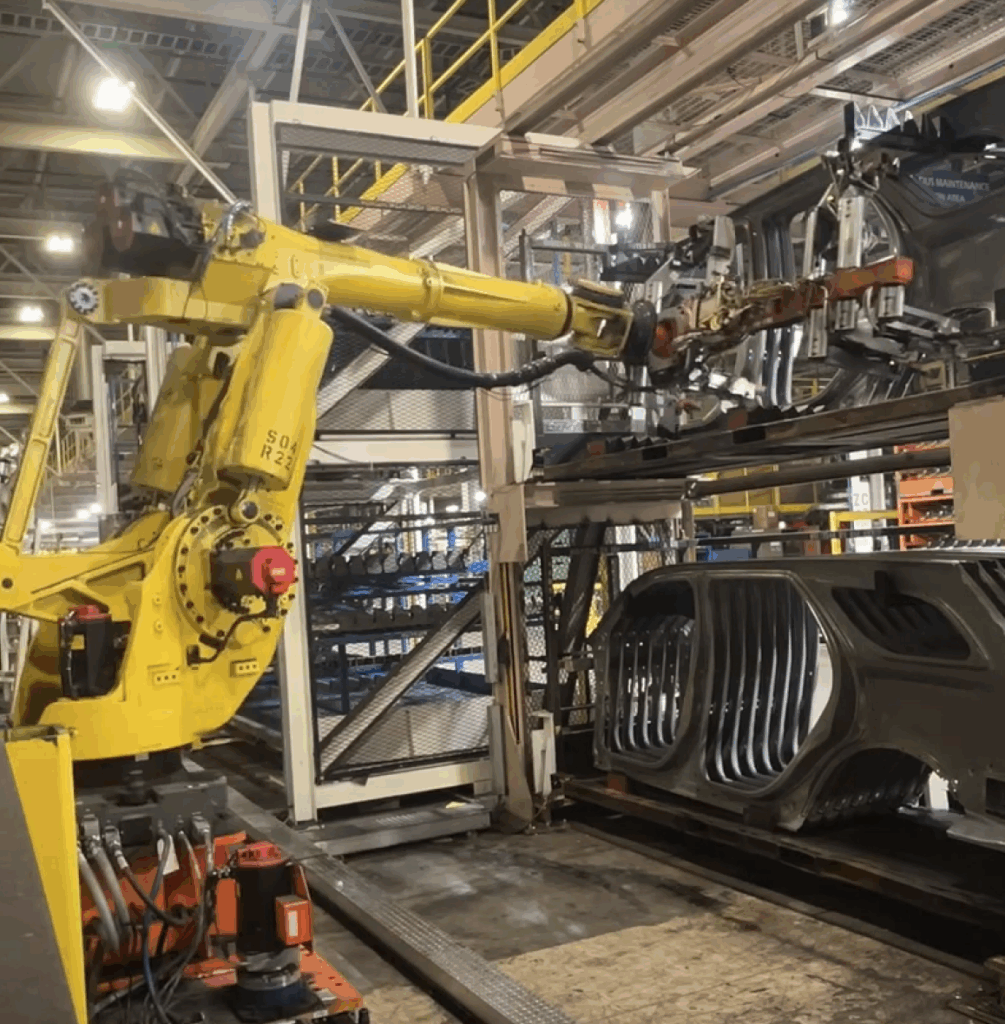

Automotive

Install new robot cells with built-in intelligence for bin picking, de-racking, and fastening.

Electronics

Add precision and repeatability to new lines, ensuring high-quality assembly and fewer defects.

Home goods

Launch new assembly cells that can adapt to changing part designs and improve uptime.

Launch smarter stations today

Talk with our team to add Inbolt to your next station. Deploy faster, cut costs, and build automation that can scale with your business.