Precision and flexibility for every stage of production

One platform to power vision-guided automation across body shop, general assembly, powertrain, and paint shop operations.

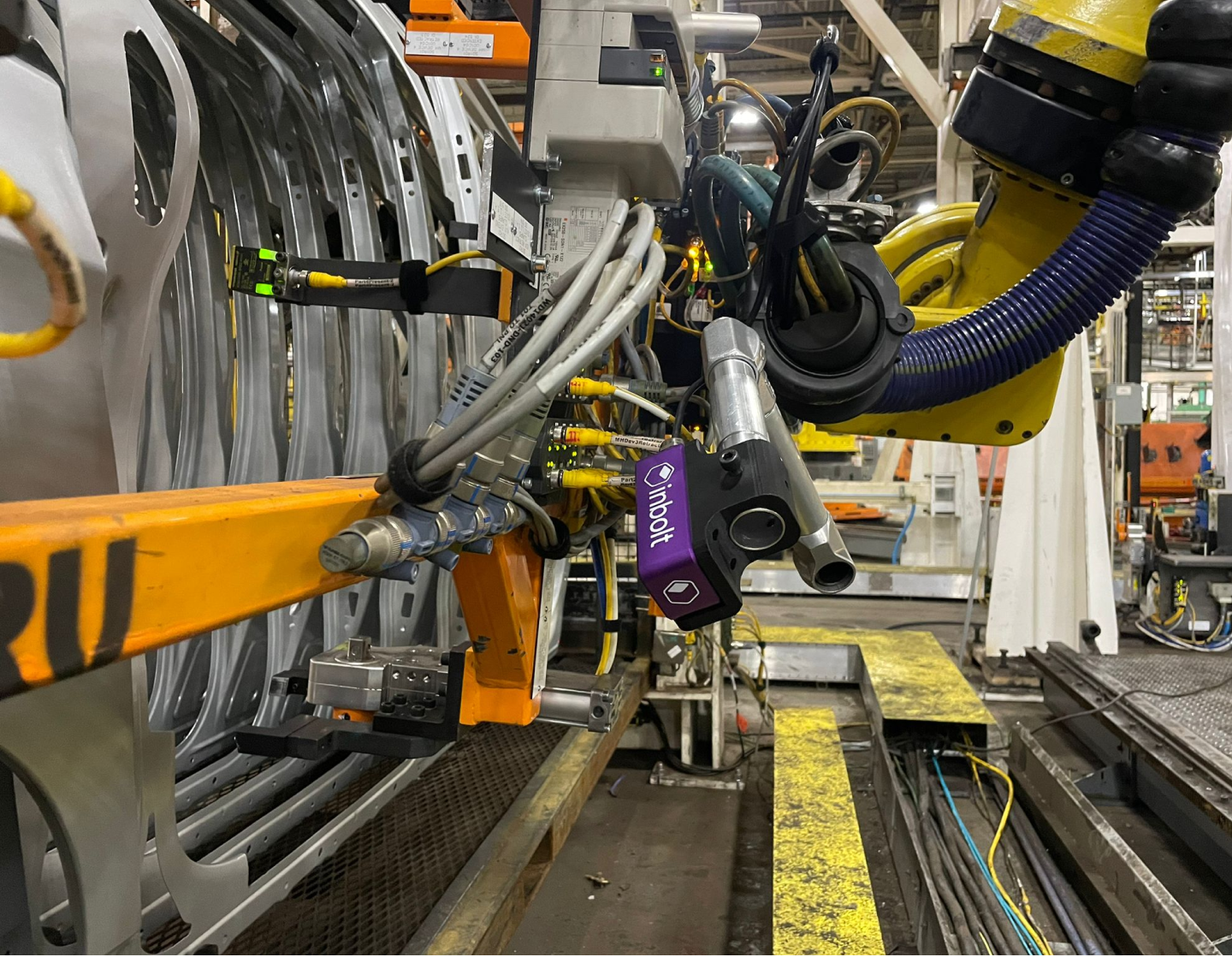

Body Shop / BIW

Handle misaligned panels and racks with ease. Inbolt’s real-time guidance keeps welding, de-racking, and panel placement precise, cutting downtime and avoiding costly rework.

General assembly

Automate part picking, placement, and fastening with CAD-trained AI. Achieve consistent torque and alignment, improving quality and reducing manual touch-ups.

Powertrain assembly

Pick, place, and assemble complex components like gears or crankshafts, even with variable positioning, for more reliable assembly and faster cycle times.

Paint shop

Material-agnostic vision detects shiny, dark, or coated parts. Maintain precision placement before and after paint, avoiding defects and keeping production flowing.

Proven results in real factories

Why automotive leaders choose Inbolt

We solve real-world production challenges. We boost uptime, quality, and ROI across automotive plants.

Speed

Deploy in days, not weeks, with CAD-based training and minimal reprogramming.

Savings

Eliminate jigs, reduce rework, and lower automation costs across multiple lines.

Scalability

One solution scales from pilot cells to enterprise-wide deployments.

Ready to automate smarter?

Talk to our automotive experts about retrofitting robots or automating new stations. We’ll help you cut downtime, speed commissioning, and achieve ROI in months.