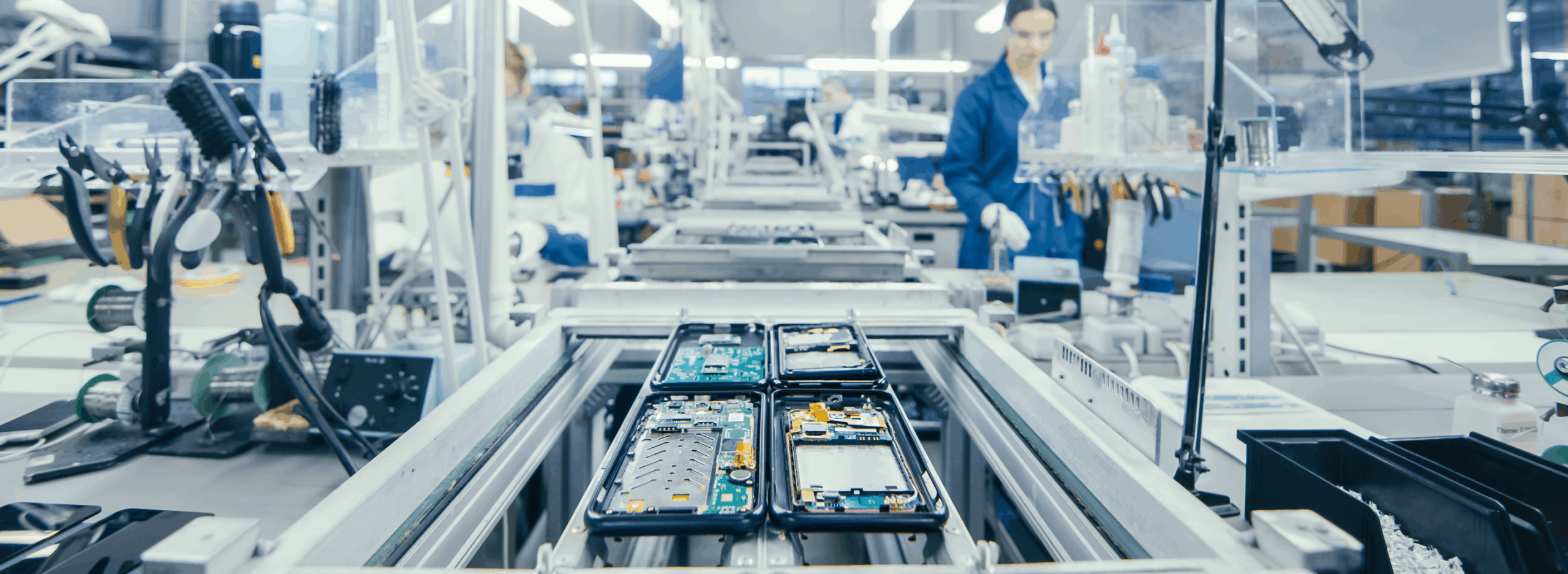

Smarter electronics production

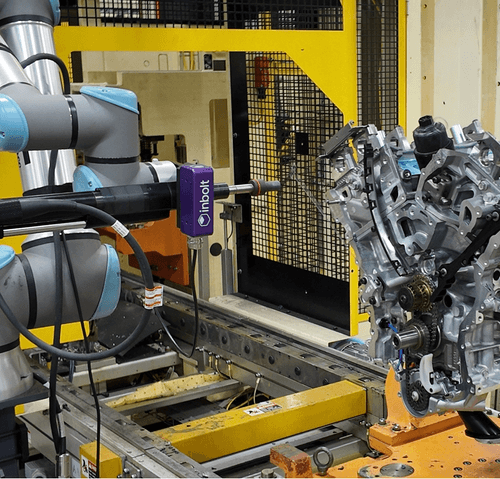

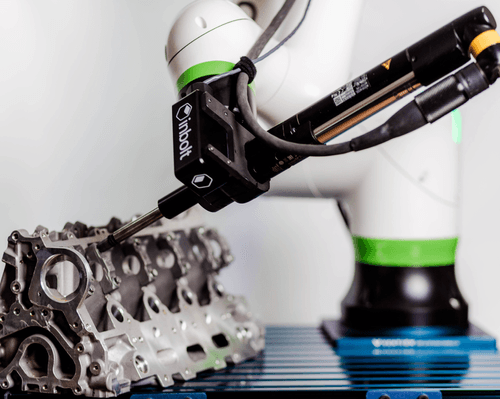

Inbolt brings real-time vision and adaptability to electronics manufacturing, helping robots stay precise and productive even with variable parts and changing production conditions.

Flexible automation

Easily adapt robot programs to new models or variants without redesigning fixtures or spending weeks reprogramming.

Consistent accuracy

Keep stations running with precise robot guidance that reduces errors and improves consistency, even with slight part misalignments.

Higher uptime

Reduce manual interventions and unplanned stops with real-time trajectory adjustments that keep production moving.

Explore more from Inbolt

Access articles, use cases, and resources to see how Inbolt drives intelligent automation worldwide.

‘Precision’ vs. ‘Accuracy’ in Robotics

NVIDIA & UR join forces with Inbolt for intelligent automation

iREX 2025 (Dec 3-6)

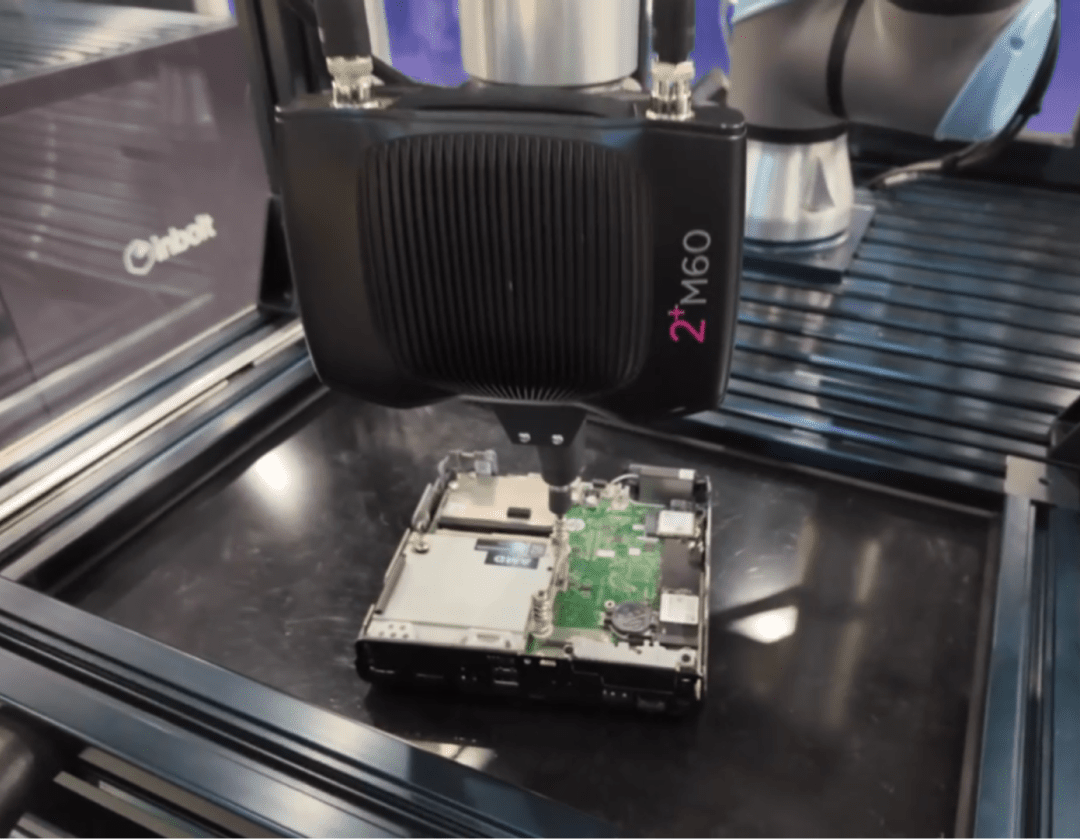

Precision, speed, and repeatability for electronics production

Build better products faster while reducing errors, waste, and manual rework.

Accuracy

Micron-level precision for placing and assembling delicate components.

Scalability

Deploy across multiple lines and sites with a repeatable, fast setup process.

Efficiency

Faster cycle times and fewer production stops keep throughput high.

Bring intelligence to your line

Talk with our team to explore how Inbolt can improve precision, reduce errors, and scale automation for your electronics manufacturing processes.