More uptime, less hassle

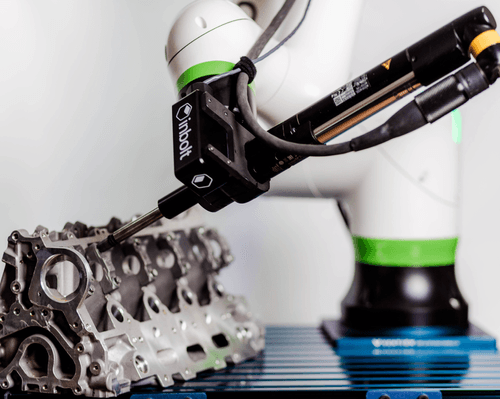

From assembly to packaging, Inbolt keeps production flowing smoothly and reduces costly stoppages.

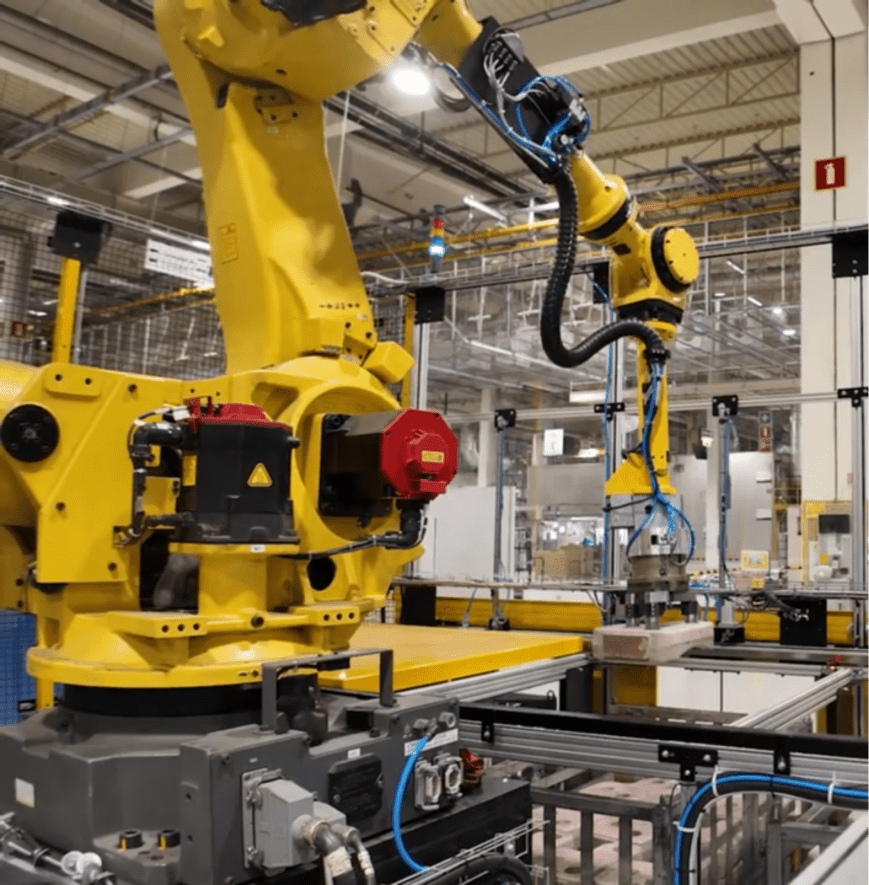

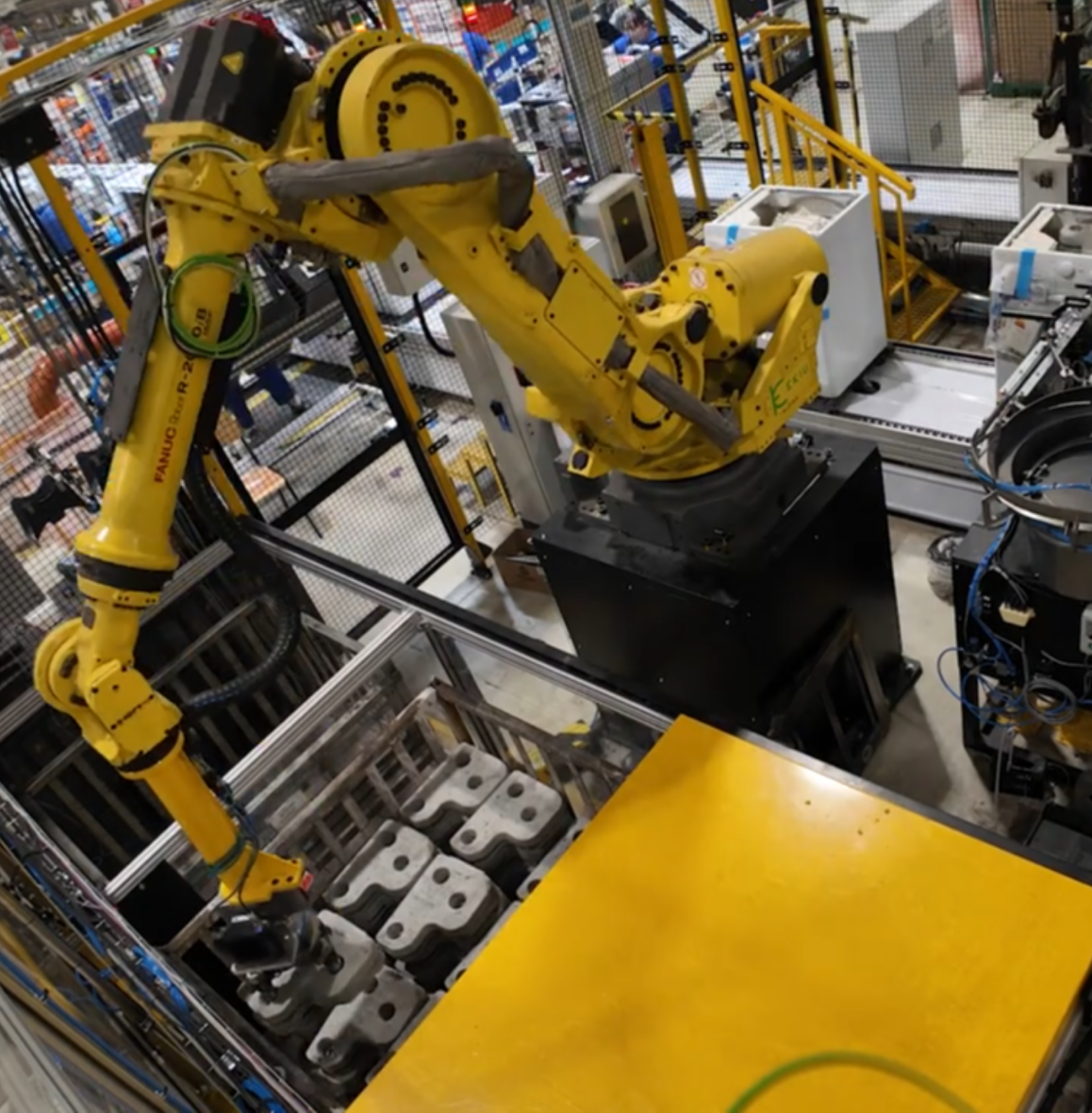

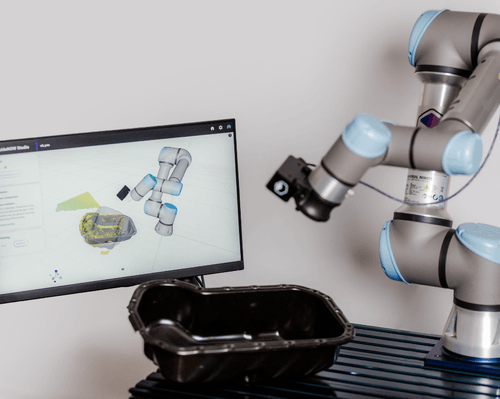

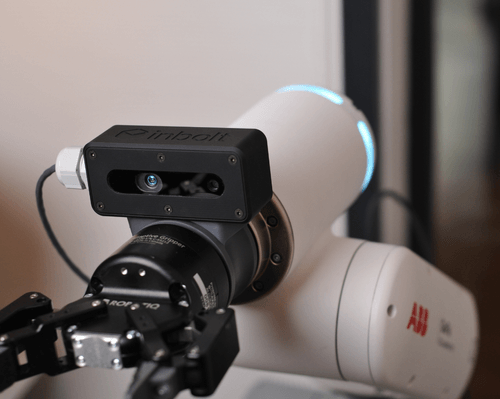

Reliable part handling

Detect and adapt to variations in part placement or geometry, reducing jams and minimizing rework on the line.

Faster commissioning

Deploy stations in hours, not weeks, with CAD-based setup and minimal need for custom fixtures or redesign.

Better line efficiency

Real-time trajectory updates keep robots working even with variability, helping improve OEE and cut cycle time.

Proven results in real factories

Explore more from Inbolt

Access articles, use cases, and resources to see how Inbolt drives intelligent automation worldwide.

‘Precision’ vs. ‘Accuracy’ in Robotics

2023 Trend Retrospection & 2024 Forecast

2024’s hottest startups in robotics and automation

2D Vision vs 3D Vision

Intelligence that keeps production moving

Scale automation with less complexity, faster deployment, and measurable ROI.

Flexibility

Easily switch between product variants or lines without major programming changes.

Productivity

Reduce downtime, avoid collisions, and keep output consistent across shifts.

ROI

Achieve payback quickly thanks to faster commissioning and fewer line interruptions.

Smarter robots for home goods

Talk to our team about how Inbolt can help retrofit your robots or power new stations to keep your production lines efficient, adaptable, and ready for tomorrow’s demand.