Proven impact, measurable results

5

< 5 mins

Training time.

Zero

Expertise required, operator-friendly.

100

100 %

On-premise. No cloud, no risk.

0.5

0.5 mm

Ultra-precise localization.

AI-powered vision software

The fastest way to give robots the vision and intelligence they need.

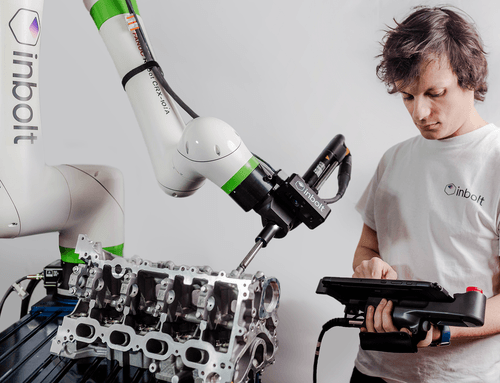

Intuitive programming

Program robot guidance applications with just a 3D design or CAD model. No complex vision parameters or manual dataset labeling required. Inbolt Studio’s interface makes it easy for anyone to deploy.

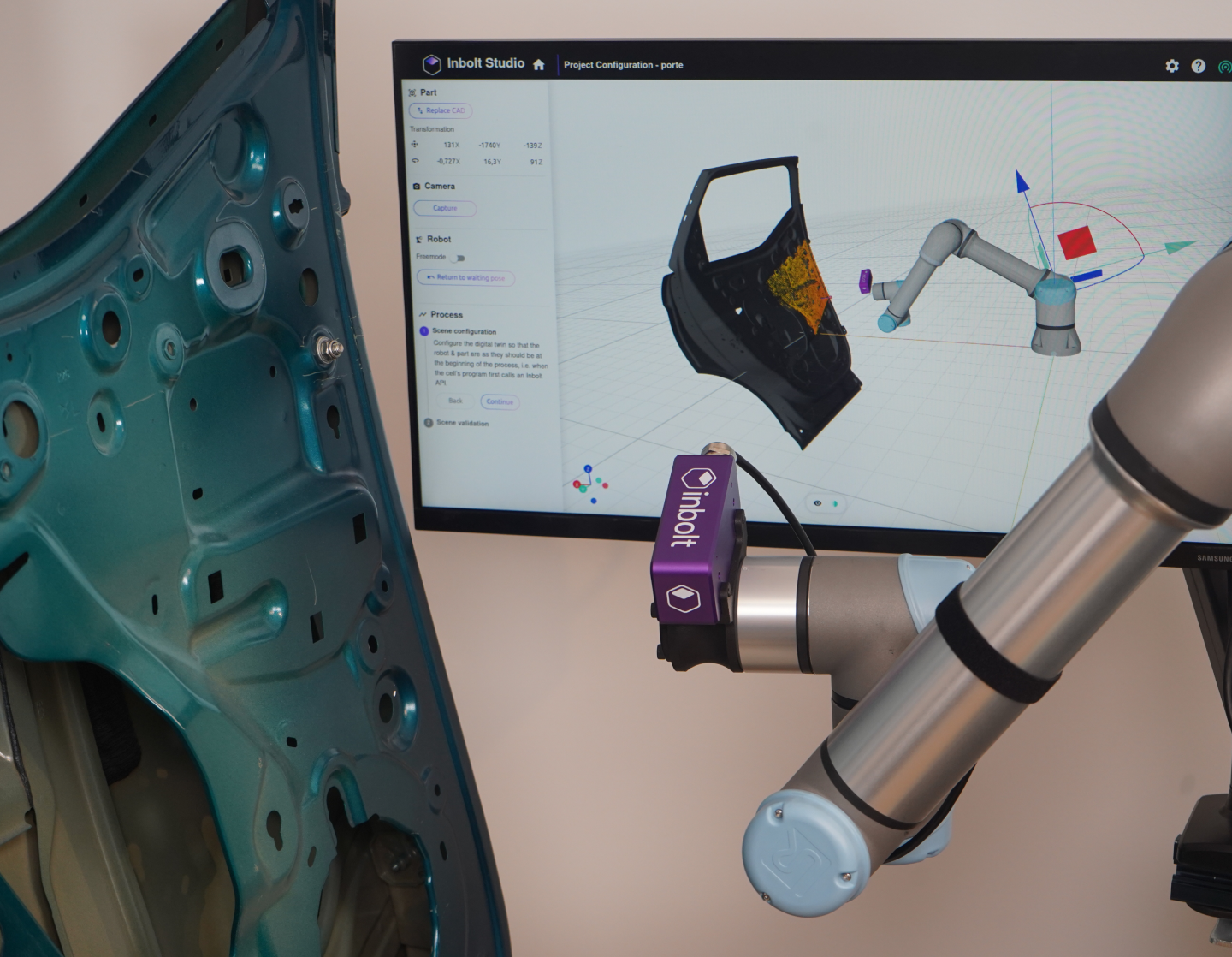

Fast deployment

Set up and train a project in under 10 minutes, entirely on-premise. From calibration to runtime, Inbolt Studio minimizes engineering time and maximizes production uptime.

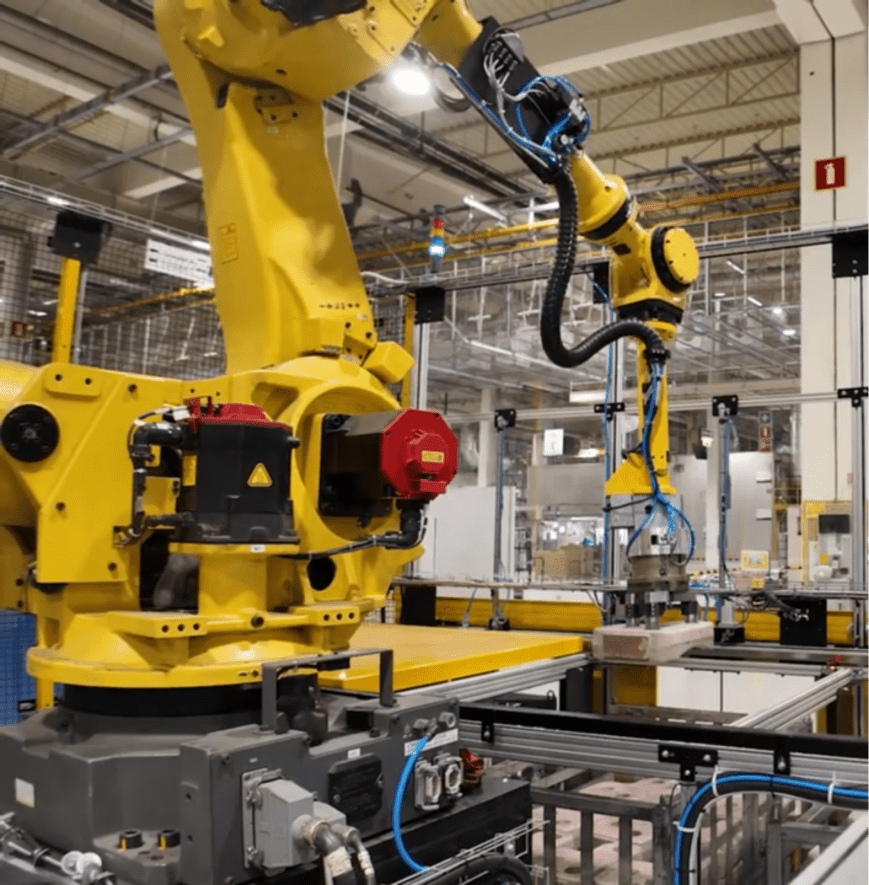

Universal AI for any part

A single AI handles all CAD models, so you don’t waste time creating datasets or retraining for each new part. Easily adapt robots to new models or variants and keep production moving.

Key features for smarter automation

Built for production, Inbolt Studio delivers the essential features to simplify setup, reduce downtime, and scale robot vision.

On-premise AI

Train and run everything locally, ensuring speed, security, and no reliance on cloud connectivity.

Multi-model storage

Store and manage up to 80 CAD models on the controller to quickly switch between production runs.

Assisted hand-eye calibration

Guided calibration process ensures fast, reliable robot-to-camera alignment without complexity.

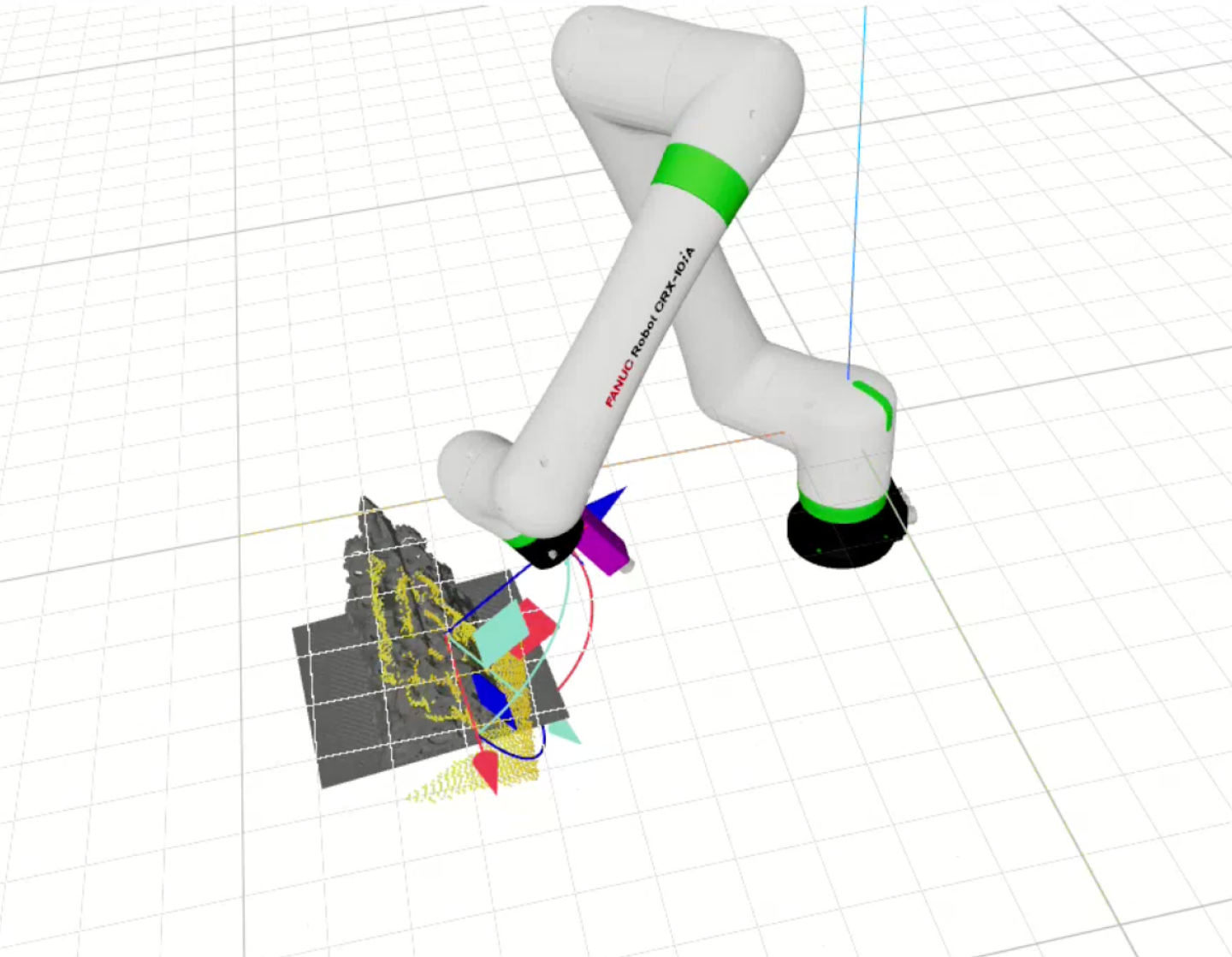

CAD-to-guidance

Import CAD files to generate precise robot vision guidance, with AI converting models into actionable trajectories quickly and accurately.

Operator-friendly UI

No vision expertise required. An intuitive interface lets operators train and launch applications fast.

Digital twin context

Link 3D design or CAD models with a basic station layout to give AI the context it needs for robust detection.

Proven results in real factories

90% fewer rejects and 12-month ROI for Stellantis Trenton.

97% less downtime and 3-month ROI from Inbolt de-racking

FAQ

Answers to common questions about Inbolt Studio software, setup, and deployment for manufacturers.

-

Inbolt Studio is the AI-powered software that transforms a 3D scan or CAD data into robot vision-guidance. It eliminates the need for complex dataset training or coding by automatically converting 3D models into vision-guided trajectories. The software handles part localization, trajectory planning, and runtime adaptability in real time. With Inbolt Studio, manufacturers can configure and deploy projects in minutes, reduce downtime, and make their robots flexible enough to handle variability in parts and processes. It’s built for factory use: easy for operators, secure on-premise, and proven in 50+ factories worldwide.

-

Setup is straightforward. Open Inbolt Studio in your browser via the Inbolt PC or desktop shortcut. The first step is to configure the Station parameters: robot, camera, and mount. Add your robot by entering its IP, brand, and name, then scan and register compatible cameras. Finally, select the provided mount and link it with the robot and camera. Once saved, your Station is configured and ready for calibration. The guided interface makes each step simple, even for operators without coding or vision expertise. Most setups are complete in under 10 minutes.

-

No. Inbolt Studio is designed to be operator-friendly. Unlike traditional vision systems that require programming skills or extensive dataset preparation, Inbolt Studio uses a universal AI trained on a 3D scan or CAD data. That means anyone on the production team can set up and deploy applications without prior coding or machine vision knowledge. The interface guides users through station setup, calibration, and deployment with assisted steps. This reduces reliance on specialized engineers, lowers commissioning time, and allows factories to scale automation faster.

-

Yes. Inbolt Studio is hardware-agnostic and integrates with leading robot brands including FANUC, ABB, Universal Robots, KUKA and more. Adding a new robot is as simple as entering its IP address (or, in the case of UR, simply naming it). The software detects and communicates directly with the robot, camera, and mount configuration. This flexibility makes Inbolt Studio future-proof for factories with mixed robot fleets. If your specific robot brand isn’t listed, Inbolt’s engineering team can evaluate compatibility and provide support.

-

Inbolt Studio runs fully on-premise. All AI training and runtime operations are handled locally, meaning there’s no reliance on cloud connectivity.. This ensures both speed and security. Manufacturers retain control of their robots, CAD data, and process information. Updates are delivered periodically, but daily operations remain fully offline, protecting your data and minimizing cybersecurity risks.

-

Manufacturers typically see ROI within 3–6 months. Inbolt Studio reduces commissioning time by enabling deployment in days instead of weeks. It eliminates the need for expensive jigs, reduces integration costs, and minimizes downtime by allowing robots to adapt in real time. Case studies show customers achieving up to 97% less downtime, 90% fewer rejects, and cycle time savings. Whether retrofitting existing robots or powering new stations, Inbolt Studio delivers measurable results quickly, making it one of the fastest-returning automation investments available.

Let’s talk vision-guided automation

From misaligned parts to moving lines, Inbolt helps robots handle real-world challenges. Fast to deploy, easy to scale, and trusted by leading manufacturers. Contact us to learn more.

Explore more from Inbolt

Access articles, use cases, and resources to see how Inbolt drives intelligent automation worldwide.

KUKA robots just got eyes: Inbolt integration is here

The Rise of Vision-Based Robotics in Automotive Manufacturing

Inbolt Joins NVIDIA Inception to Accelerate AI-Driven Automation