The generalist model for robot intelligence

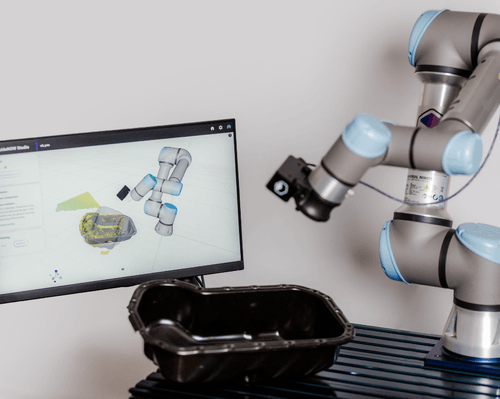

Inbolt has built the ultimate intelligence layer for factories: a general-purpose model for robot guidance that sees, understands, and acts in real time. Pre-trained on diverse manufacturing data and fine-tuned with just a CAD model, it delivers unmatched precision without photos, manual teaching, or complex reprogramming. This is the brain that makes every robot smarter from day one.

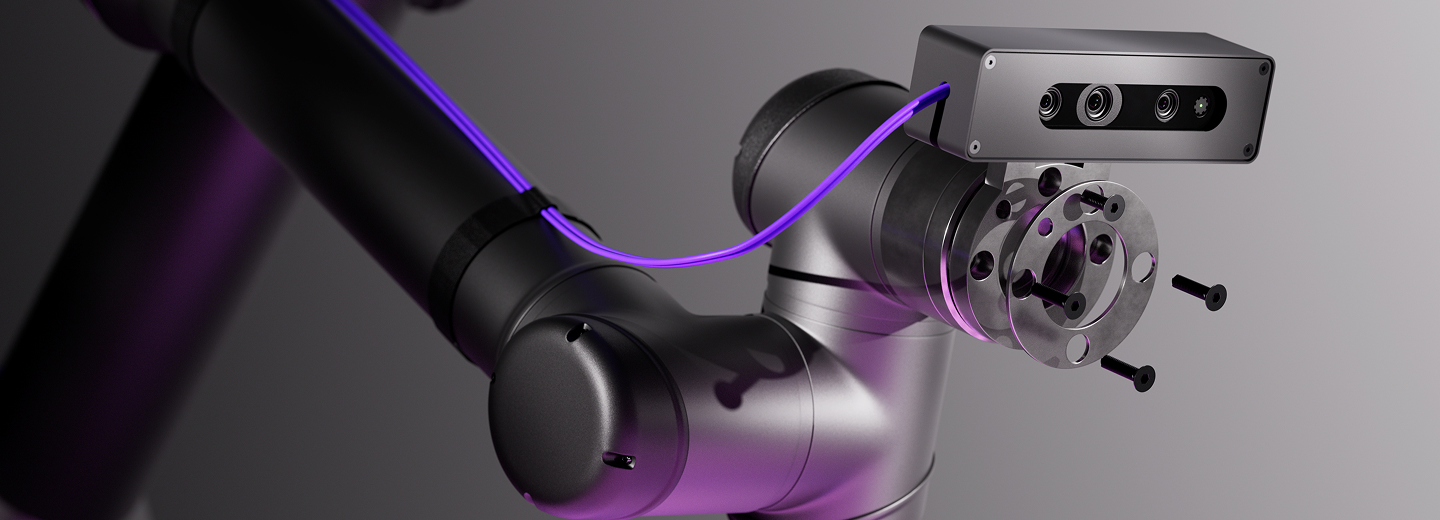

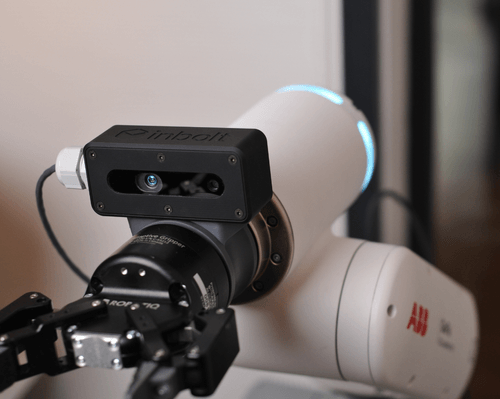

Powering robots with real-time vision

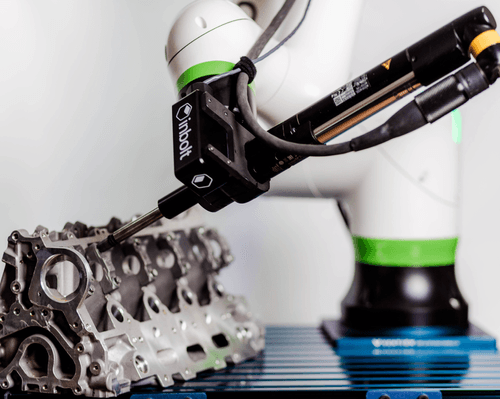

Inbolt combines robot-mounted 3D vision, edge AI, and real-time trajectory calculation to deliver flexible, lighting-agnostic, and highly precise robot guidance for any production environment.

Built to Solve Real Factory Challenges

Faster deployment, lower automation costs, and higher productivity with fewer errors.

Deploy in days, not weeks

Reduce commissioning time with pre-trained AI and easy setup. Get production running faster.

Cut integration costs

Eliminate expensive jigs, fixtures, and rigid setups while reducing hardware and engineering costs.

Boost uptime and quality

Adaptive, real-time guidance minimizes pick errors, rework, and production stoppages.

Proven impact, measurable results

5

< 5 mins

Training time

80

< 80 ms

Perception to motion

80

80 +

Parts handled with ease

70

70 +

Factories using Inbolt

Explore more from Inbolt

Access articles, use cases, and resources to see how Inbolt drives intelligent automation worldwide.

‘Precision’ vs. ‘Accuracy’ in Robotics

2023 Trend Retrospection & 2024 Forecast

2024’s hottest startups in robotics and automation

2D Vision vs 3D Vision

Talk to our automation experts

Ready to explore how Inbolt’s technology can retrofit your robots or power new cells? Our team will help you plan fast deployment, reduce costs, and boost uptime.