Reliable 3D Tracking in Any Lighting Condition

Lighting is one of the biggest obstacles for traditional 3D vision systems. In real factories, light is constantly changing: morning sunlight from a skylight, reflections from overhead LEDs, shadows from moving equipment, even flashing signals. These changes distort projected patterns and create noisy depth maps, leading to unstable or inaccurate part detection.

Geometry-Based AI Vision

Inbolt’s AI doesn’t rely on projected light or contrast. Instead, it understands the geometry of each part, learned directly from CAD. This makes the system independent from brightness, reflections or color variations.

Built for Real Factory Lighting

As the video demonstrates, Inbolt maintains real-time tracking in:

-

Bright, uncontrolled daylight

-

Low light and full darkness

-

Harsh glare and flashing light

Ambient light, shadows and exposure changes don’t interfere with performance. The system continues tracking the part consistently because it recognizes shape, not light.

Lighting-Agnostic Guidance for Automation

Whether installed near windows, under variable LEDs or next to reflective surfaces, Inbolt delivers stable, lighting-agnostic vision guidance for bin picking and complex automation tasks—without additional lighting or controlled setups.

Explore more from Inbolt

Access similar articles, use cases, and resources to see how Inbolt drives intelligent automation worldwide.

The Circular Factory - How Physical AI Is Enabling Sustainable Manufacturing

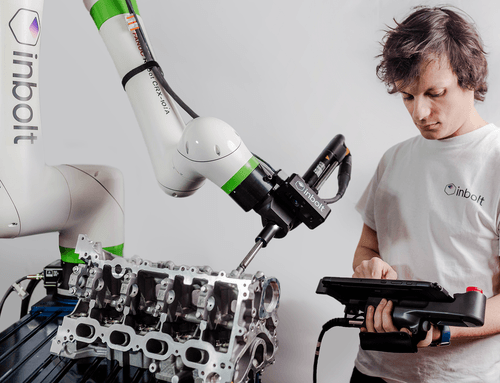

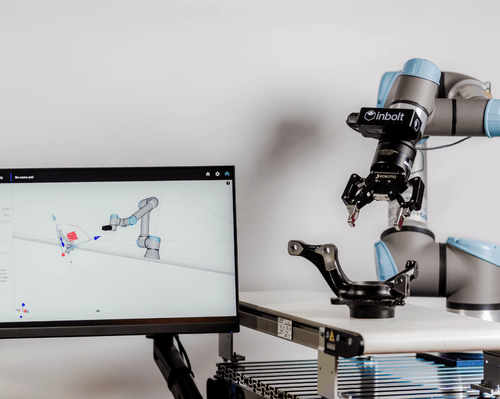

NVIDIA & UR join forces with Inbolt for intelligent automation

KUKA robots just got eyes: Inbolt integration is here

Albane Dersy named one of “10 women shaping the future of robotics in 2025”

Want to Sound Smart About Vision‑Guidance for Robots?

Inbolt Joins NVIDIA Inception to Accelerate AI-Driven Automation

Inbolt x UR AI Accelerator: Ushering in the Era of Vision-Guided Robotics by Default