The Circular Factory – How Physical AI Is Enabling Sustainable Manufacturing

From concept to reality, circular manufacturing should take center stage.

Across the manufacturing world, sustainability has evolved from a visionary concept to an operational imperative. The rise of digital transformation, automation, and AI is accelerating this shift by helping manufacturers not only produce more efficiently but also more responsibly.

At the heart of this transformation is the circular economy, a model that redefines how we design, make, use, and reuse products. In industries like automotive and electronics, global leaders are embedding circular principles throughout their value chains, from product design and production to end-of-life recovery.

And with AI-guided robotics entering the factory floor, the circular economy is no longer just about recycling but about rethinking efficiency from the start of production.

How Physical AI supports a circular economy

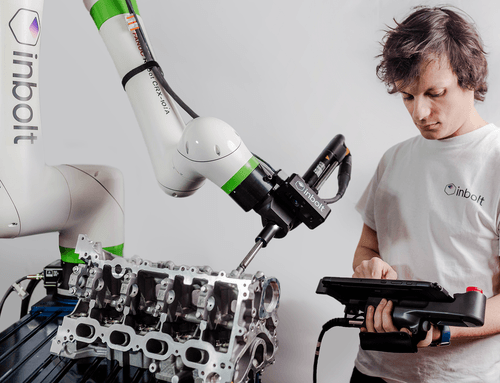

At Inbolt, we believe that sustainability and performance go hand in hand. Our vision-guidance technology and generalist AI model help robots operate with unmatched precision, efficiency, and adaptability to drastically reduce waste and resource use across manufacturing processes.

Here’s how Inbolt contributes to more sustainable, circular operations:

1) Resource efficiency in automotive manufacturing

Every misplaced weld, screw, or component consumes unnecessary materials, time, and energy.

By guiding robots with real-time precision, Inbolt’s Physical AI reduces defects directly at the source, preventing wasted materials and cutting avoidable emissions.

Simulation: how a factory producing 500 vehicles/day cuts waste and CO₂ with Inbolt

-

Each vehicle contains 20,000 parts

-

Initial defect rate: 2% = 200,000 defective parts/month

-

Half are scrapped → 10 tonnes of waste/month

-

With Inbolt reducing defects by 50%:

→ 5 tonnes less waste/month

→ ≈ 60 tonnes less waste/year

→ ≈ 120 tonnes of CO₂ avoided annually

For automotive manufacturers, these gains translate to major resource savings across metals, plastics, and composites, while improving overall line efficiency and production uptime.

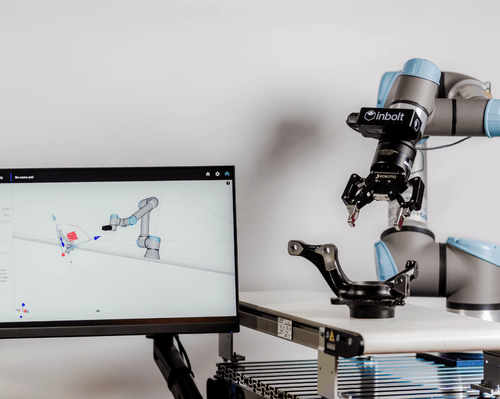

2) Ultra-low-energy AI architecture

Traditional AI systems rely on cloud-based computing, requiring high data transfer and power consumption. Inbolt’s Physical AI runs locally, directly on embedded controllers with the robot. This drastically lowers energy use and carbon emissions while maintaining high-speed, on-device processing.

Simulation: comparing energy use of 1,000 robots – traditional Cloud AI vs. Inbolt on-premise AI

Assuming each robot is trained twice per month:\

| AI System | Annual Energy Use | Annual CO₂ Emissions |

|---|---|---|

| 🔴 Traditional Cloud AI | 4.8 million kWh | 2,160 tonnes CO₂ |

| 🟢 Inbolt Physical AI | 2,400 kWh | 1.1 tonnes CO₂ |

With Inbolt this leads to:

→ 99.95% less energy used

→ ≈ 2,159 tonnes of CO₂ avoided per year

By running inference and training directly at the edge, manufacturers achieve the same performance with a fraction of the power — a significant step toward low-carbon, intelligent production systems.

3) Reducing electronic waste through precision

In electronics manufacturing, even minor alignment errors can make high-value components unusable.

Inbolt’s real-time AI vision minimizes these defects, eliminating unnecessary rework and preventing hundreds of tonnes of material waste each year — directly supporting circular design and production principles.

Case in point: Stellantis’ path to smarter, cleaner production

One of the clearest examples of Inbolt’s impact comes from Stellantis’ Trenton plant in the U.S., where bolt tightening errors caused frequent rejects and manual rework. Using Inbolt’s real-time AI vision, Stellantis reduced bolt tightening rejects by 91%, improving efficiency, reducing waste, and avoiding costly line slowdowns or infrastructure upgrades.

In a traditional linear model, such inefficiencies create downstream waste and energy loss. By eliminating unnecessary rework and enabling automation to adapt dynamically, Inbolt helped Stellantis move closer to the principles of circular manufacturing: doing more with less.

Toward sustainable automation

As industries accelerate toward net-zero goals, automation can no longer be designed purely for speed, it must be designed for sustainability. Physical AI plays a key role in achieving that balance.

By giving robots the ability to see, think, and act in real time, Inbolt empowers manufacturers to:

- Minimize material waste and rework

- Cut energy consumption at scale

- Extend the life and flexibility of existing production lines

- Build factories that are adaptive, efficient, and sustainable by design

The circular economy is already taking shape on factory floors. With Inbolt’s Physical AI, sustainability becomes a way for smart factories to stay efficient, competitive, and built to last.

Explore more from Inbolt

Access similar articles, use cases, and resources to see how Inbolt drives intelligent automation worldwide.

Reliable 3D Tracking in Any Lighting Condition

NVIDIA & UR join forces with Inbolt for intelligent automation

KUKA robots just got eyes: Inbolt integration is here

Albane Dersy named one of “10 women shaping the future of robotics in 2025”

Want to Sound Smart About Vision‑Guidance for Robots?

Inbolt Joins NVIDIA Inception to Accelerate AI-Driven Automation

Inbolt x UR AI Accelerator: Ushering in the Era of Vision-Guided Robotics by Default