Customer stories

See how leading manufacturers like Stellantis, Ford, and Beko use Inbolt’s AI-powered vision to boost uptime, cut costs, and automate the most challenging tasks — from bin picking to fastening — with speed and precision.

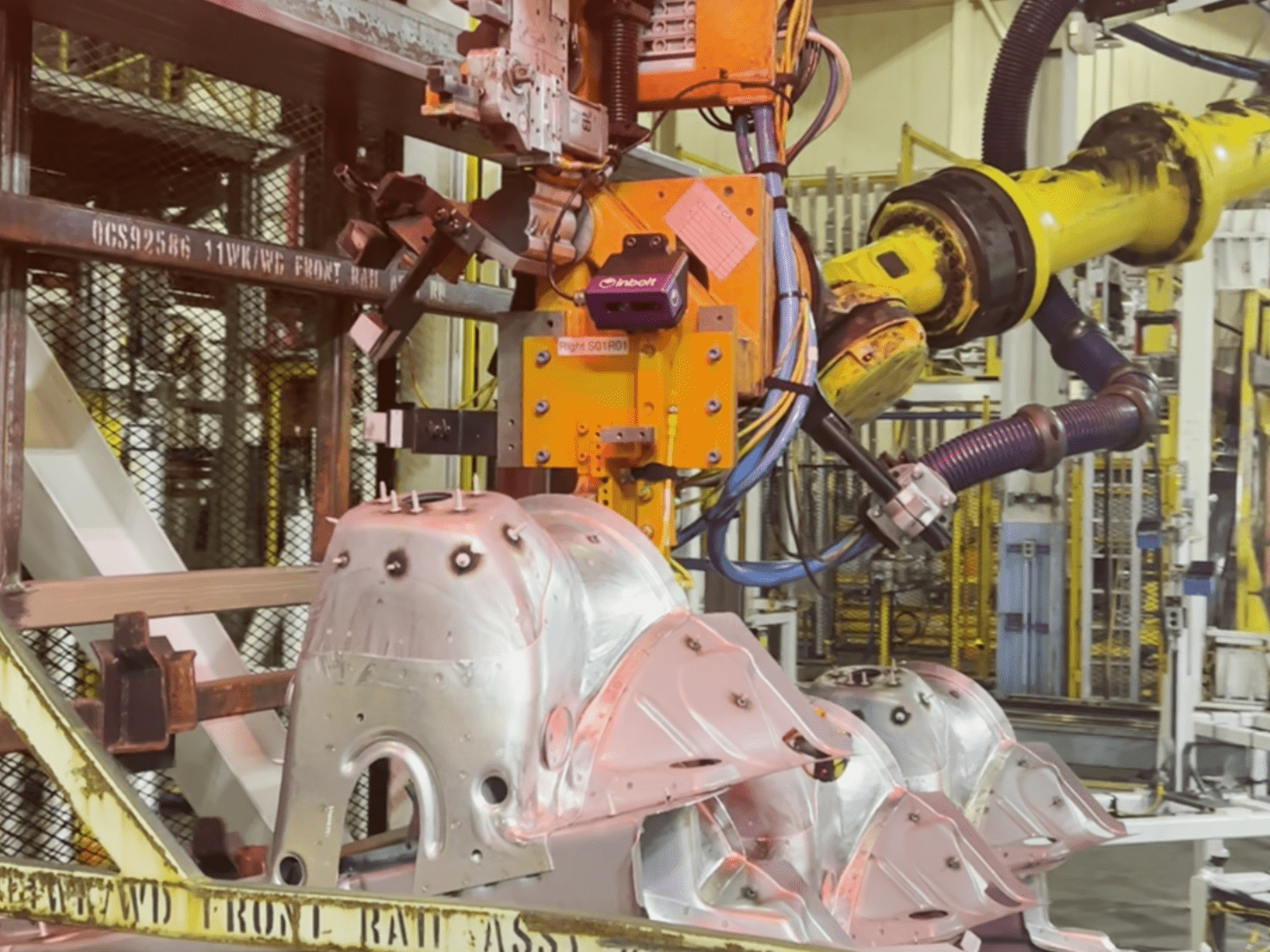

Automotive OEM enhances automation performance by leveraging Inbolt’s intelligent vision and organizational capabilities

Customer: Stellantis Location: Detroit, USA Application: Static de-racking of underbody framing rails Approach: In-house automation…

70% improvement in cycle efficiency for glue dispensing

At Stellantis’ Detroit Assembly Complex – Jefferson, Inbolt’s AI-powered 3D vision guidance system enabled precise…

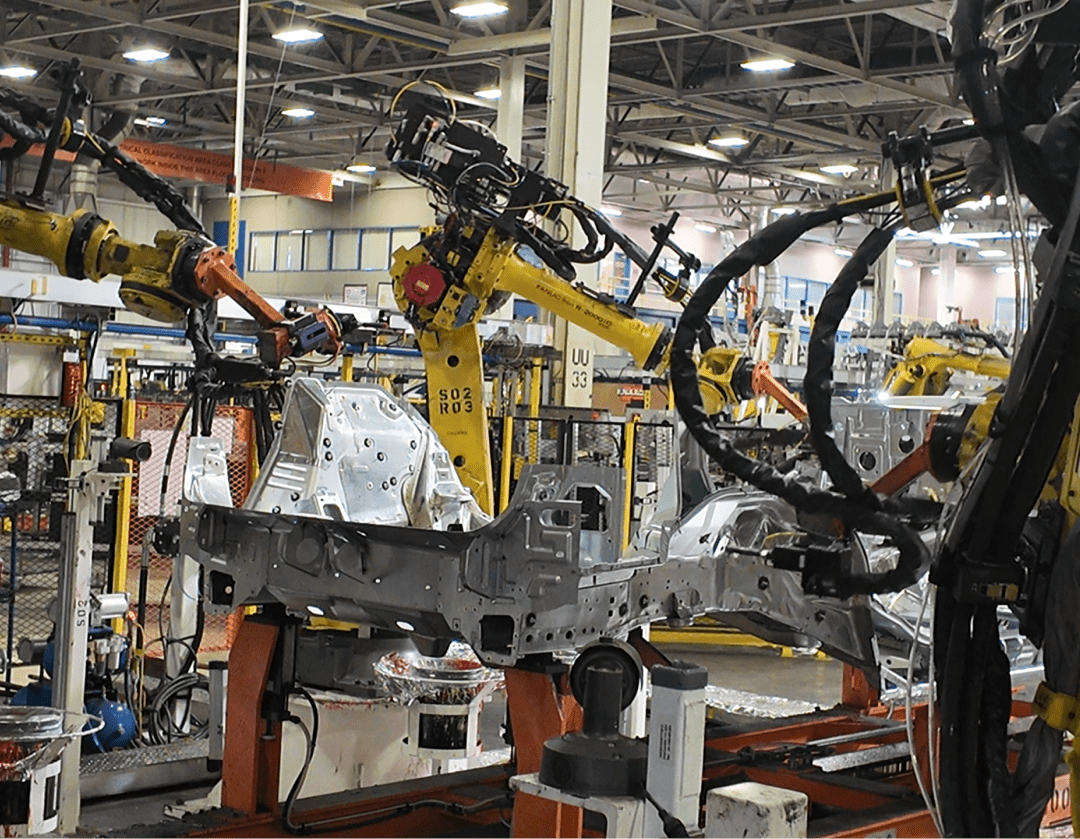

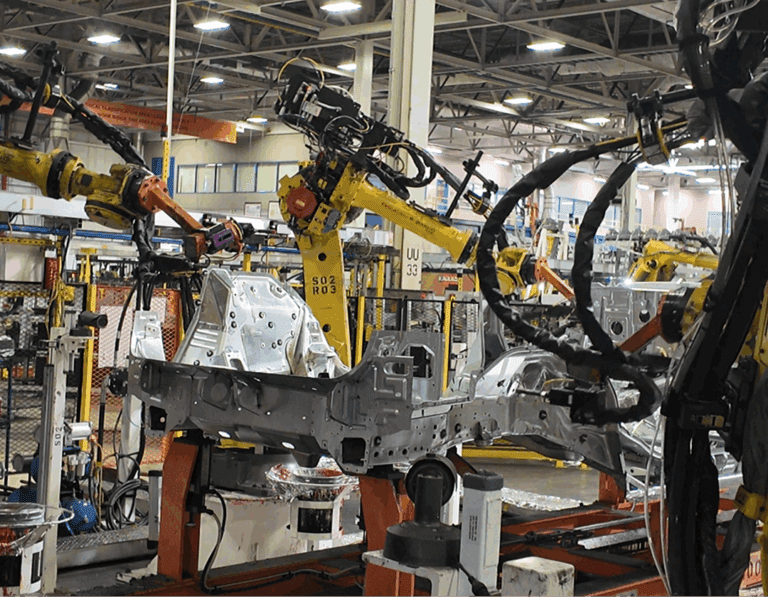

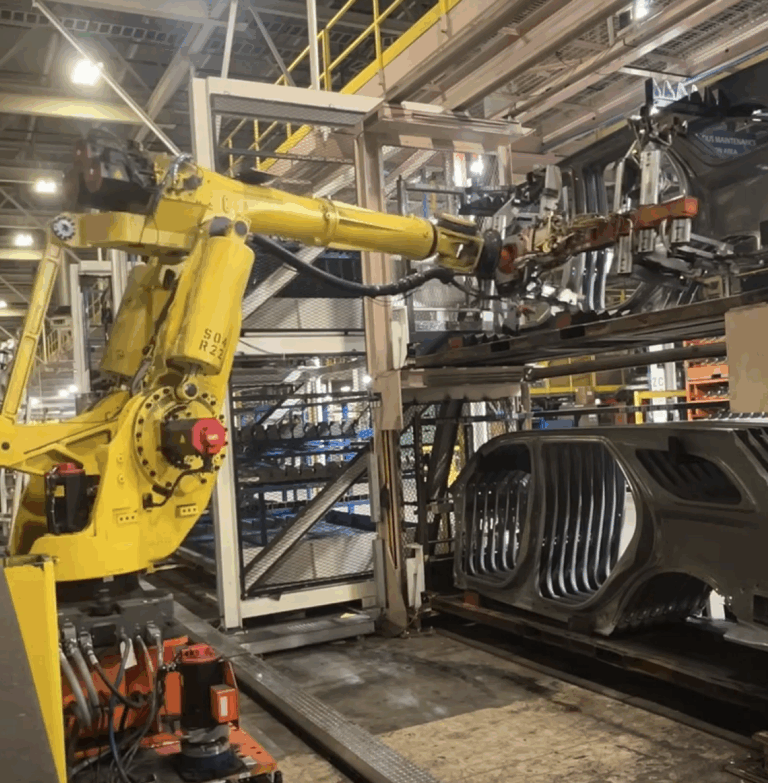

30% Cycle Time Reduction in Automotive Pick & Place

At Stellantis’ Detroit Assembly Complex, Inbolt’s AI-powered 3D vision system enabled robots to handle liftgates…

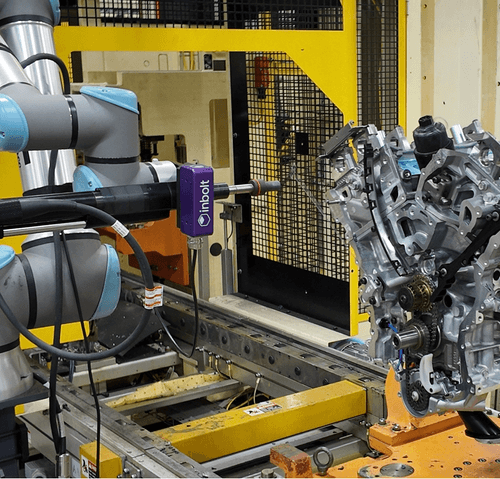

Stellantis Reduces Tightening Rejects by 91% with Inbolt’s Vision-Guidance at their Trenton Plant

Stellantis reduced bolt tightening rejects by 90.5% at their Trenton plant using Inbolt’s vision-guided robotics,…

Stellantis Valenciennes Cuts 2.7 Tons in Daily Handling with Inbolt’s Vision-Guided Automation

Stellantis Valenciennes boosted automation with Inbolt’s vision-guided system, overcoming challenges like inconsistent part positioning and…

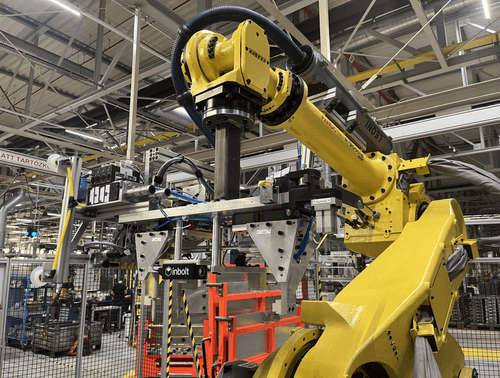

Stellantis Enhances Bodyshop Efficiency by 97% with Inbolt’s Vision-Guided De-Racking Solution

Stellantis cut downtime by 97% at its Detroit plant by retrofitting a FANUC cell with…

Stellantis automates semi-structured depalletizing with Inbolt

Stellantis automated cylinder head depalletizing using FANUC robots and Inbolt, overcoming challenges of uneven parts…

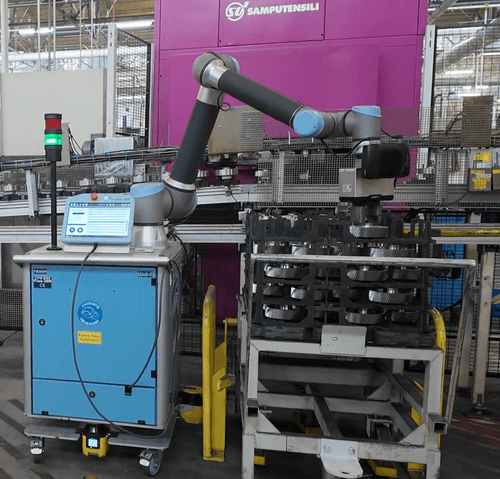

Stellantis Automates Small Parts Pick and Place

The Stellantis plant in Verrone, Italy has automated the pick & place of hydraulic clutch…

Beko Automates Stones Picking from Bin & Precise Placing

Picking stones from a bin and positioning them precisely on pins with GuideNOW High-Precision.

Stellantis automates ferro-alloy leveling and filter insertion inside molds

The Stellantis plant in Skoczow, Poland automated a line with wide variety of molds references…

Stay updated

Be the first to hear about Inbolt’s latest product updates, case studies, and industry insights. Sign up for our newsletter and never miss a beat on the future of automation.