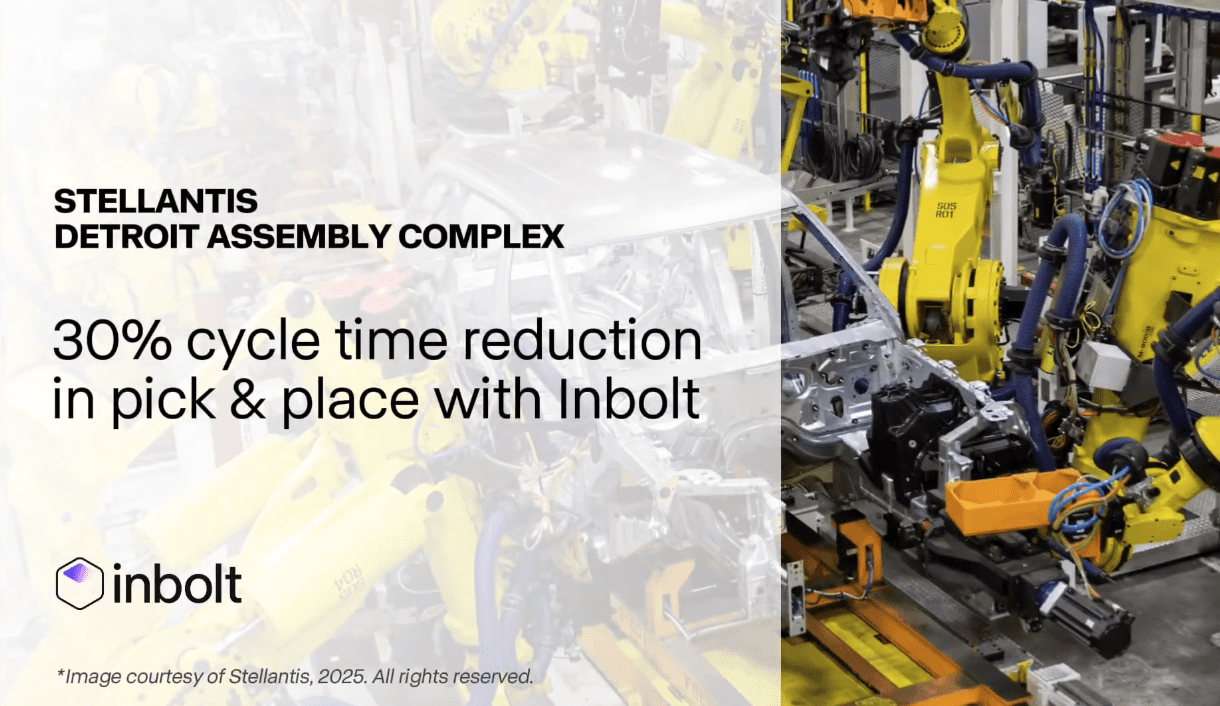

30% Cycle Time Reduction in Automotive Pick & Place

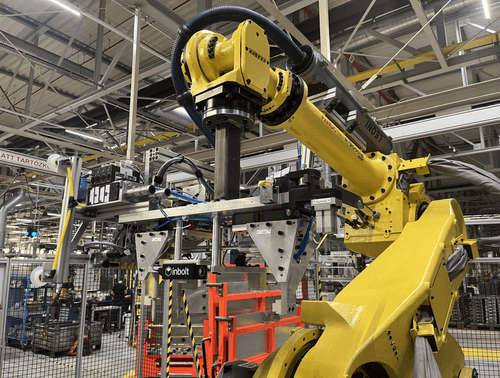

At Stellantis’ Detroit Assembly Complex, Inbolt’s AI-powered 3D vision system enabled robots to handle liftgates with 30% faster cycle times, 10x repeatability, and a 3–6 month projected ROI.

Customer: Stellantis

Location: Detroit, United States

Return on Investment: 3-6 months

Challenge

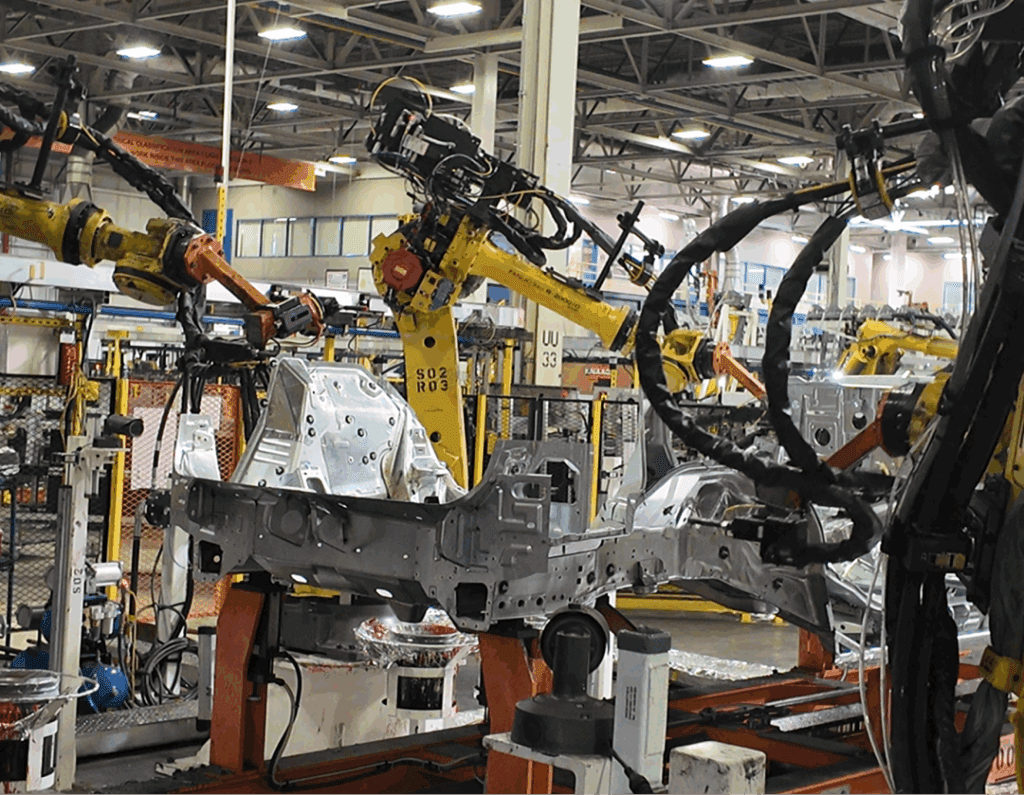

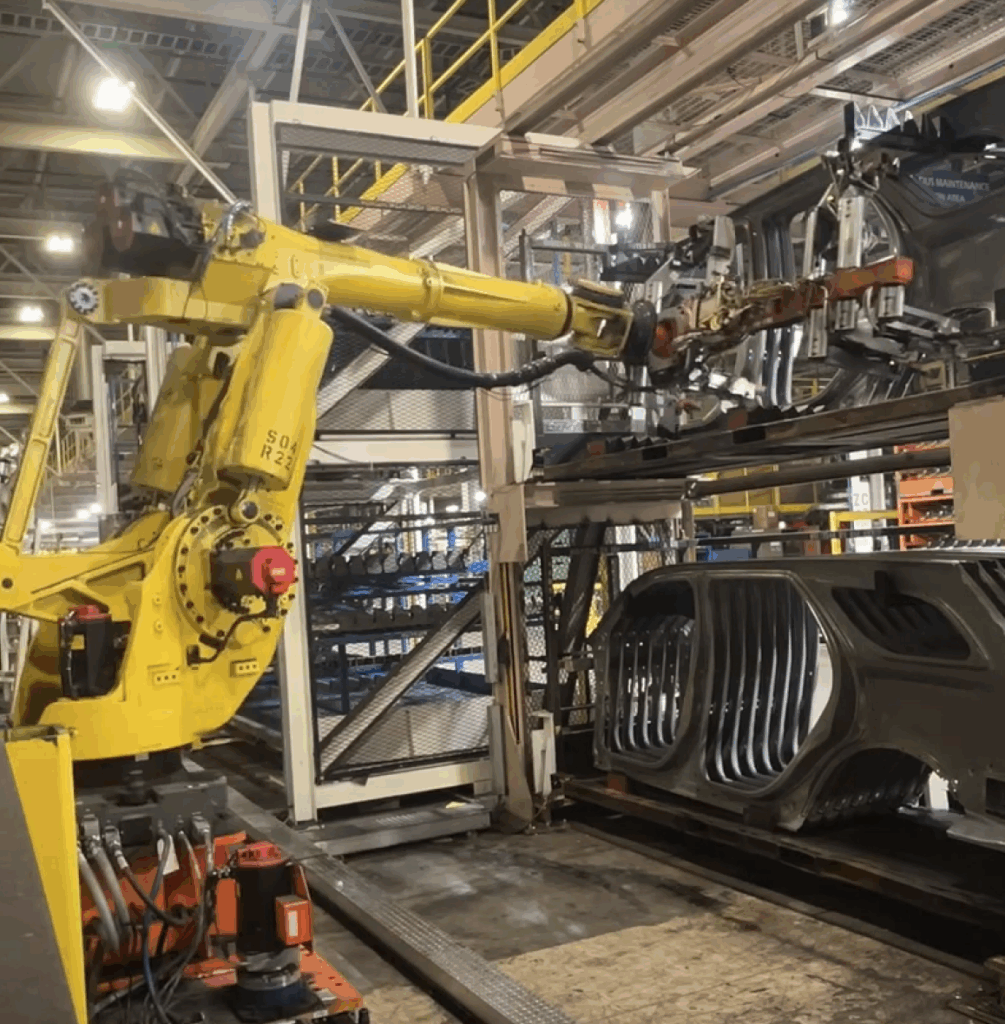

At Stellantis’ Detroit Assembly Complex – Jefferson (Body Shop), one station was dedicated to material handling of the liftgate. Robots were tasked with picking the liftgate part of a car body, but the existing method relied on a laser scanner to slowly search and align the part before each pick. This process was time-consuming, caused delays, and required operators to constantly monitor uptime.

Solution

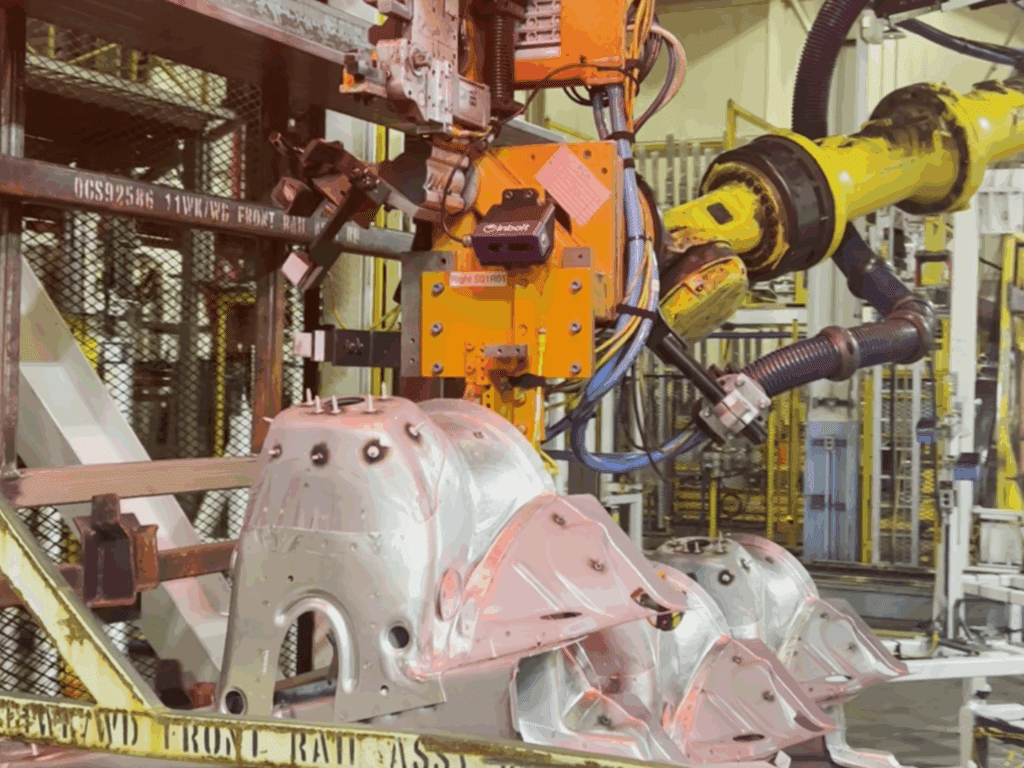

Inbolt deployed its AI and 3D vision system with a camera mounted directly on the FANUC robot’s gripper.

- The laser still provided a rough position estimate.

- Inbolt instantly refined the part’s exact position and orientation in 3D.

- The robot was able to perform a perfect pick in a fraction of the time, no slow scanning required.

This meant faster, more reliable cycles and less operator oversight.

Success Metrics

- 30% faster cycle time

- 10x improvement in repeatability

- Higher uptime with no collisions

- Reduced costs

Explore more from Inbolt

Access similar articles, use cases, and resources to see how Inbolt drives intelligent automation worldwide.

Automotive OEM enhances automation performance by leveraging Inbolt’s intelligent vision and organizational capabilities

70% improvement in cycle efficiency for glue dispensing

Stellantis Reduces Tightening Rejects by 91% with Inbolt’s Vision-Guidance at their Trenton Plant

Stellantis Valenciennes Cuts 2.7 Tons in Daily Handling with Inbolt’s Vision-Guided Automation

Stellantis Enhances Bodyshop Efficiency by 97% with Inbolt’s Vision-Guided De-Racking Solution

Stellantis automates semi-structured depalletizing with Inbolt

Stellantis Automates Small Parts Pick and Place