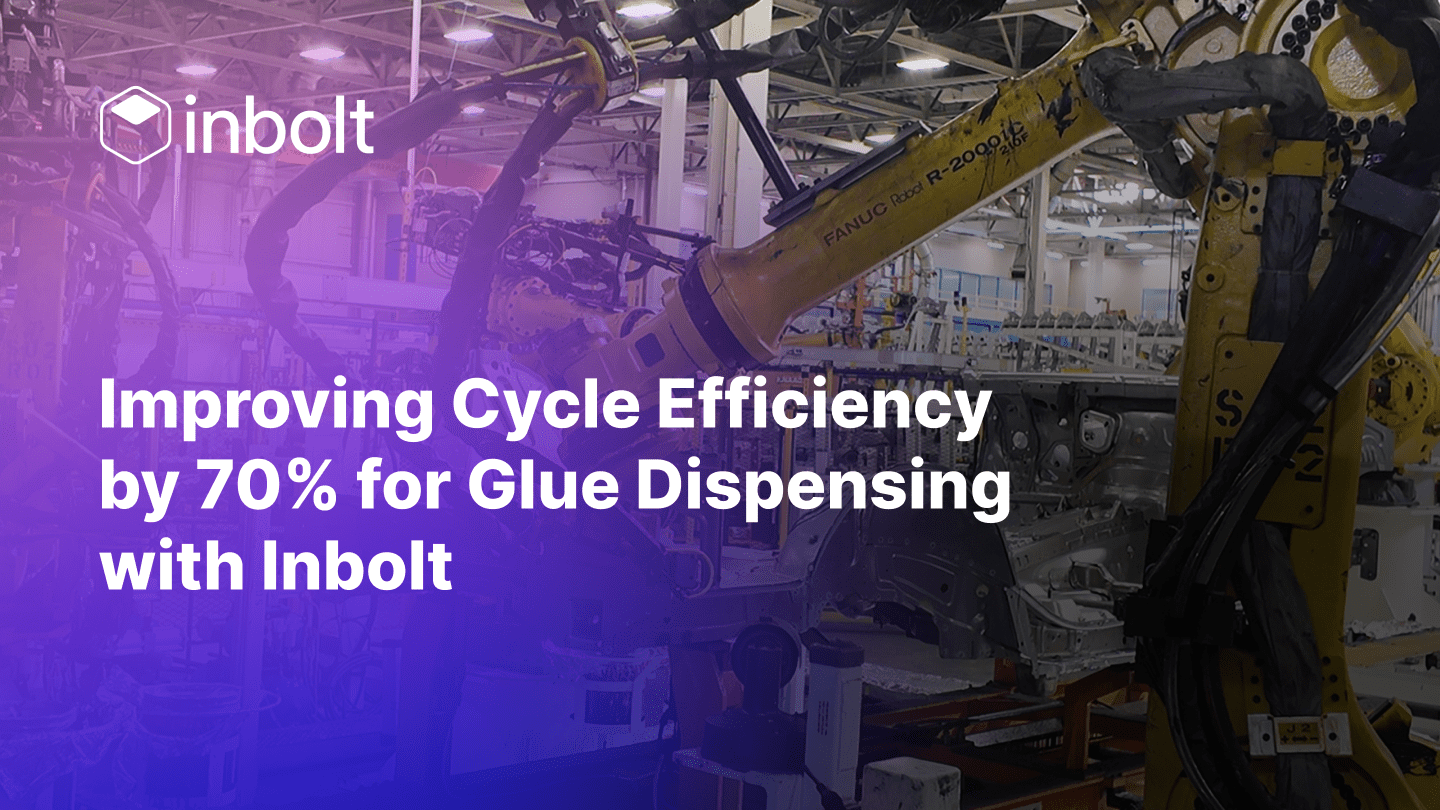

70% improvement in cycle efficiency for glue dispensing

At Stellantis’ Detroit Assembly Complex – Jefferson, Inbolt’s AI-powered 3D vision guidance system enabled precise and consistent glue dispensing, increasing station reliability and reducing unplanned pauses by 70%.

Customer: Stellantis’ Detroit Assembly Complex – Jefferson

Location: Detroit, United States

Return on Investment: 6 months

Challenge

Before Inbolt’s implementation, the robotic dispensing station applying glue on assembled vehicle bodies occasionally experienced minor misalignments between the robot’s programmed path and the workpiece position. Even small deviations, sometimes as little as 4mm, could affect the end-effector’s trajectory, leading to manual interventions for cleanup and recalibration.

With Inbolt, the system now continuously detects the exact position of each workpiece in real time, automatically adjusting the robot’s path. This has virtually eliminated interruptions, improved cycle time consistency, and increased overall production efficiency on the line.

Solution

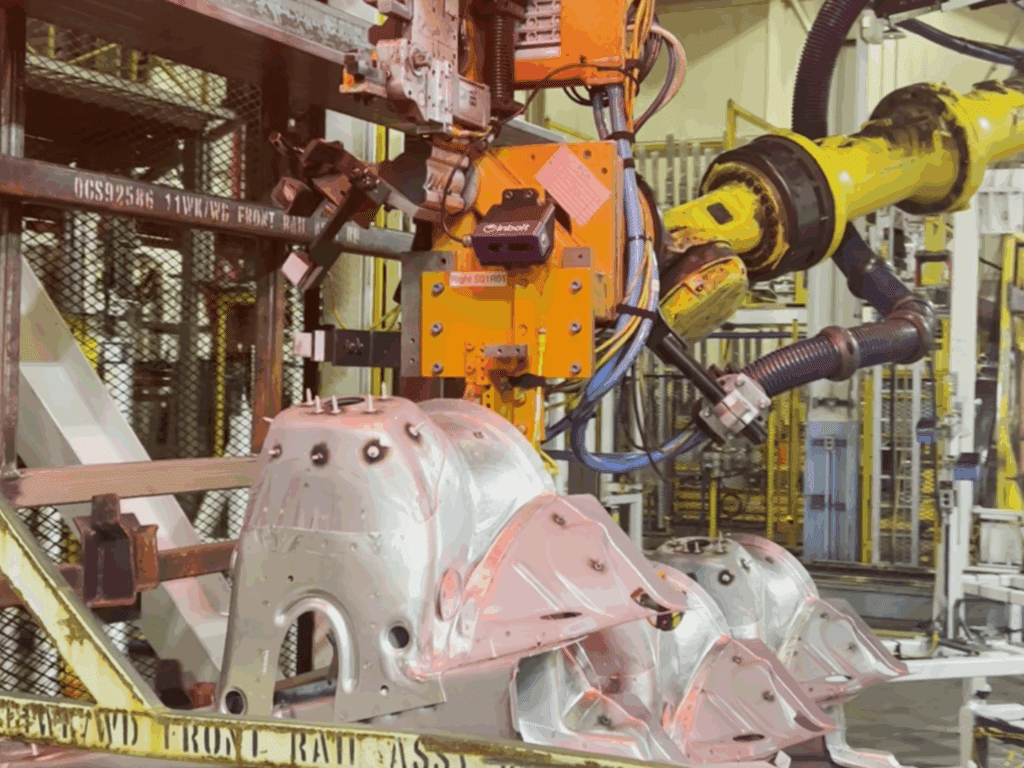

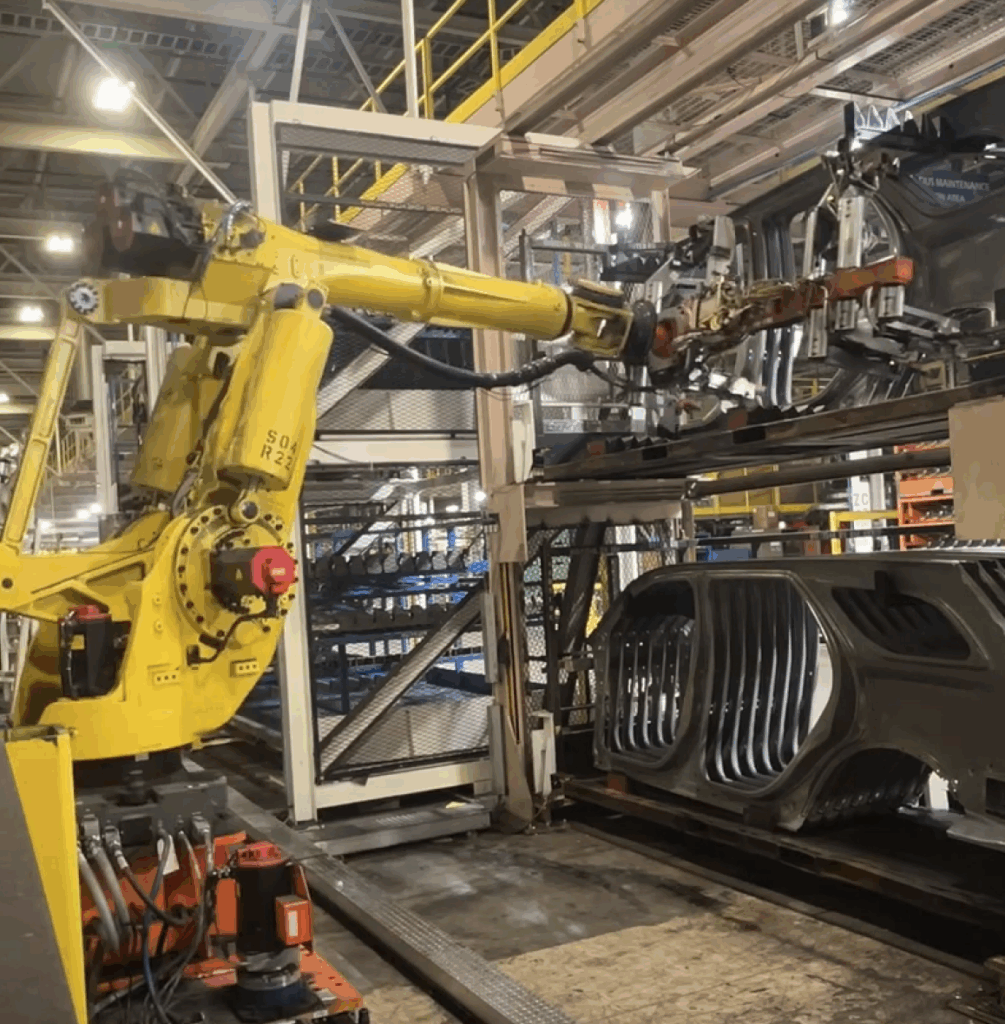

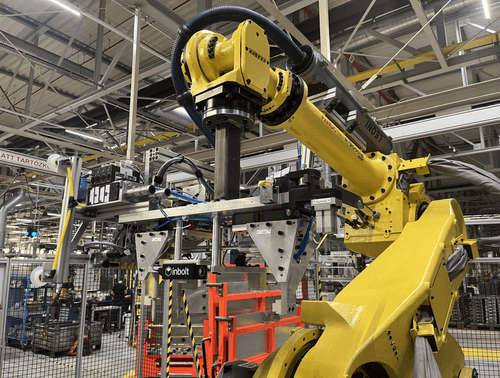

To address this issue, Stellantis implemented Inbolt’s AI and 3D vision guidance system on the FANUC robot responsible for dispensing. The Inbolt camera is mounted directly on the end effector of a custom-designed mount.

The system was configured with four distinct projects, each corresponding to a specific section of the vehicle body. Before dispensing on each section, Inbolt’s solution captures a real-time 3D scan of the surface, automatically adjusting the robot’s trajectory to account for any positional variation.

This dynamic adjustment ensures that every bead of glue was applied precisely, regardless of small differences between assembled units.

Success Metrics

- 70% improvement in cycle efficiency related to end-effector tip breakage.

- Consistent, high-quality glue application across all vehicle sections.

- Minimized production interruptions.

Explore more from Inbolt

Access similar articles, use cases, and resources to see how Inbolt drives intelligent automation worldwide.

Automotive OEM enhances automation performance by leveraging Inbolt’s intelligent vision and organizational capabilities

30% Cycle Time Reduction in Automotive Pick & Place

Stellantis Reduces Tightening Rejects by 91% with Inbolt’s Vision-Guidance at their Trenton Plant

Stellantis Valenciennes Cuts 2.7 Tons in Daily Handling with Inbolt’s Vision-Guided Automation

Stellantis Enhances Bodyshop Efficiency by 97% with Inbolt’s Vision-Guided De-Racking Solution

Stellantis automates semi-structured depalletizing with Inbolt

Stellantis Automates Small Parts Pick and Place