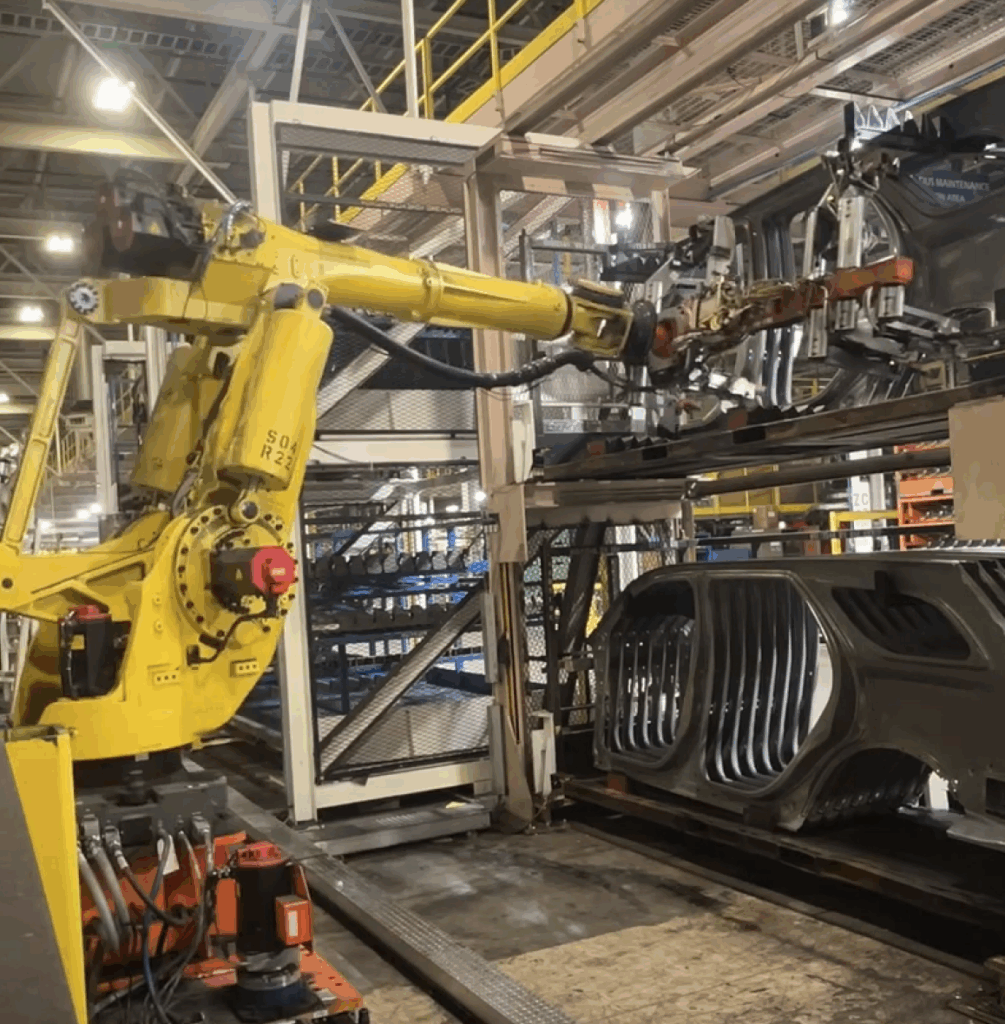

Stellantis automates ferro-alloy leveling and filter insertion inside molds

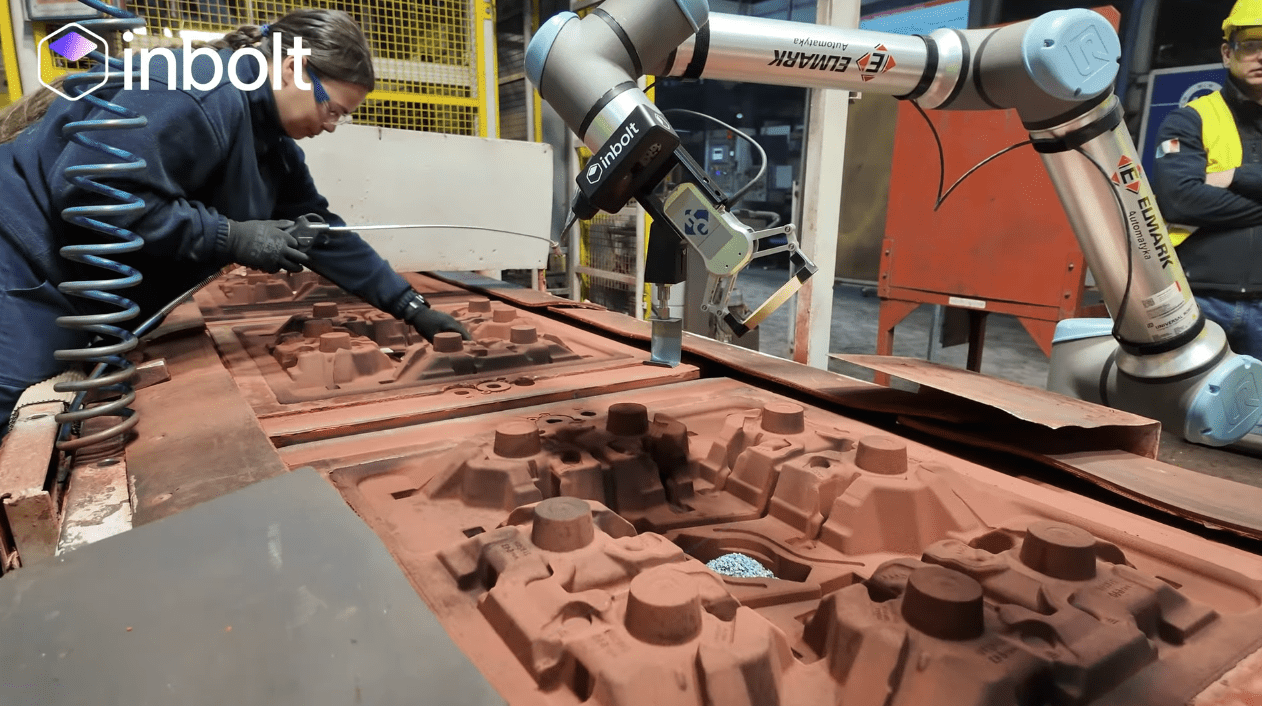

The Stellantis plant in Skoczow, Poland automated a line with wide variety of molds references without the need for custom indexing systems thanks to GuideNOW and with the support of Drim Robotics as integrators.

Customer: Stellantis

Location: Skoczow, Poland

Return on Investment: 9 months

Challenge

Stellantis aimed to automate the repetitive task of leveling ferro-alloy poured into molds and inserting filters on a fast-moving production line. The automation presented several key challenges:

- Molds arrive quickly at the station and stop in non-repeatable positions.

- A wide variety of mold models are processed, requiring an easy-to-program vision solution.

- The cycle time is extremely short, so the vision system had to operate efficiently without slowing down the process.

Solution

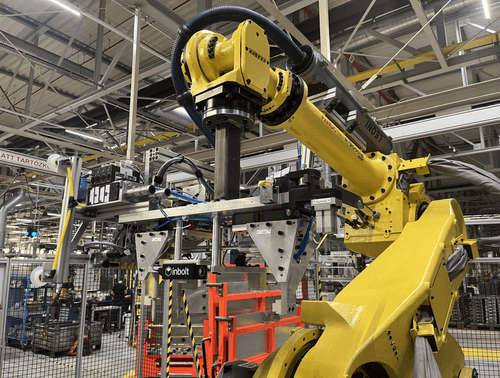

Stellantis chose the GuideNOW Real-time solution. The system enables a collaborative robot (cobot) to locate molds as they enter the camera’s field of view and adjust the robot’s trajectory in real-time. With GuideNOW, Stellantis can program new mold variants in under 10 minutes, allowing even non-expert users to automate different mold variants quickly and efficiently.

Benefits

- Cost-Efficient Automation: No changes to the existing production environment were needed, reducing automation costs.

- Ease of Use: the integrator, Drim Robotics, can program new mold variants in GuideNOW rapidly, facilitating quick adaptation to new production requirements.

- Flexibility: Cobots allow workers to continue operating alongside the automated station, enhancing flexibility and operational efficiency.

Explore more from Inbolt

Access similar articles, use cases, and resources to see how Inbolt drives intelligent automation worldwide.

70% improvement in cycle efficiency for glue dispensing

30% Cycle Time Reduction in Automotive Pick & Place

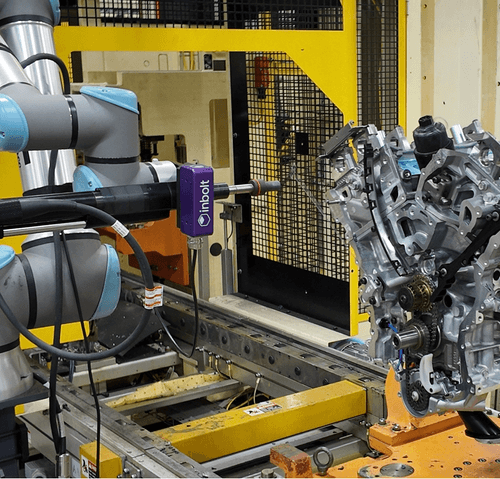

Stellantis Reduces Tightening Rejects by 91% with Inbolt’s Vision-Guidance at their Trenton Plant

Stellantis Valenciennes Cuts 2.7 Tons in Daily Handling with Inbolt’s Vision-Guided Automation

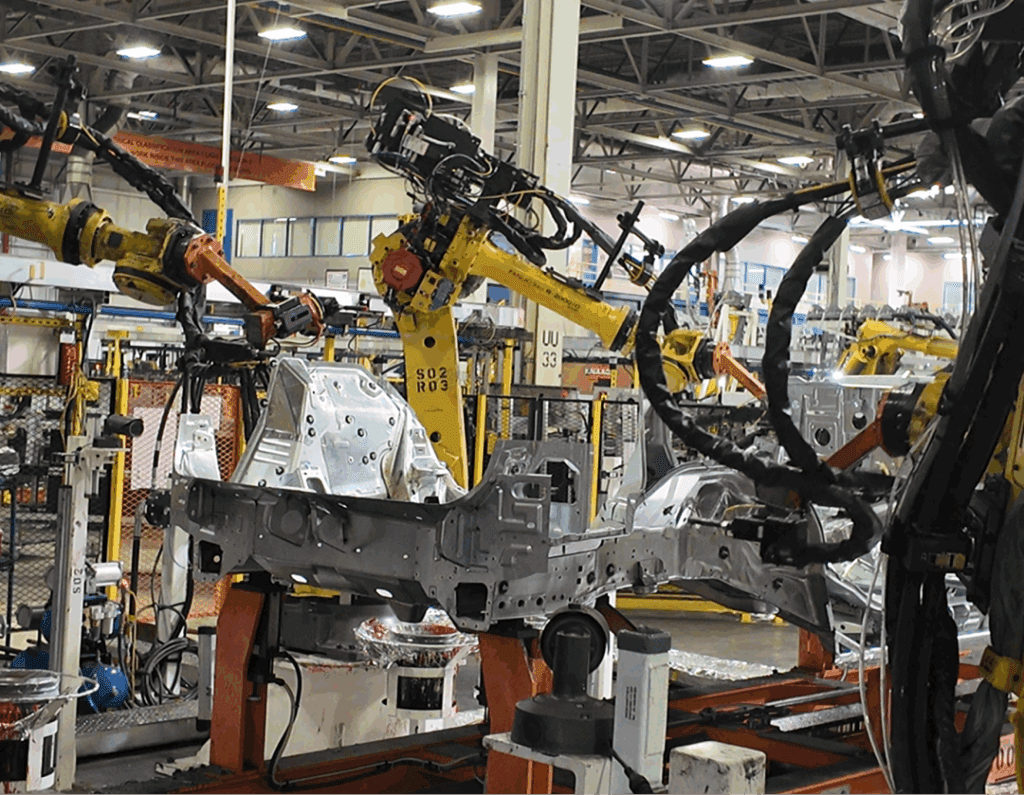

Stellantis Enhances Bodyshop Efficiency by 97% with Inbolt’s Vision-Guided De-Racking Solution

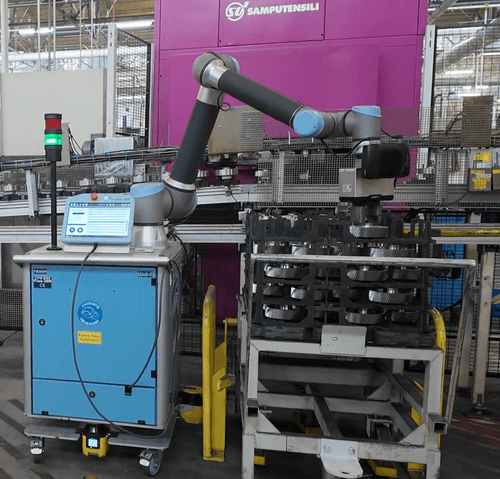

Stellantis automates semi-structured depalletizing with Inbolt

Stellantis Automates Small Parts Pick and Place