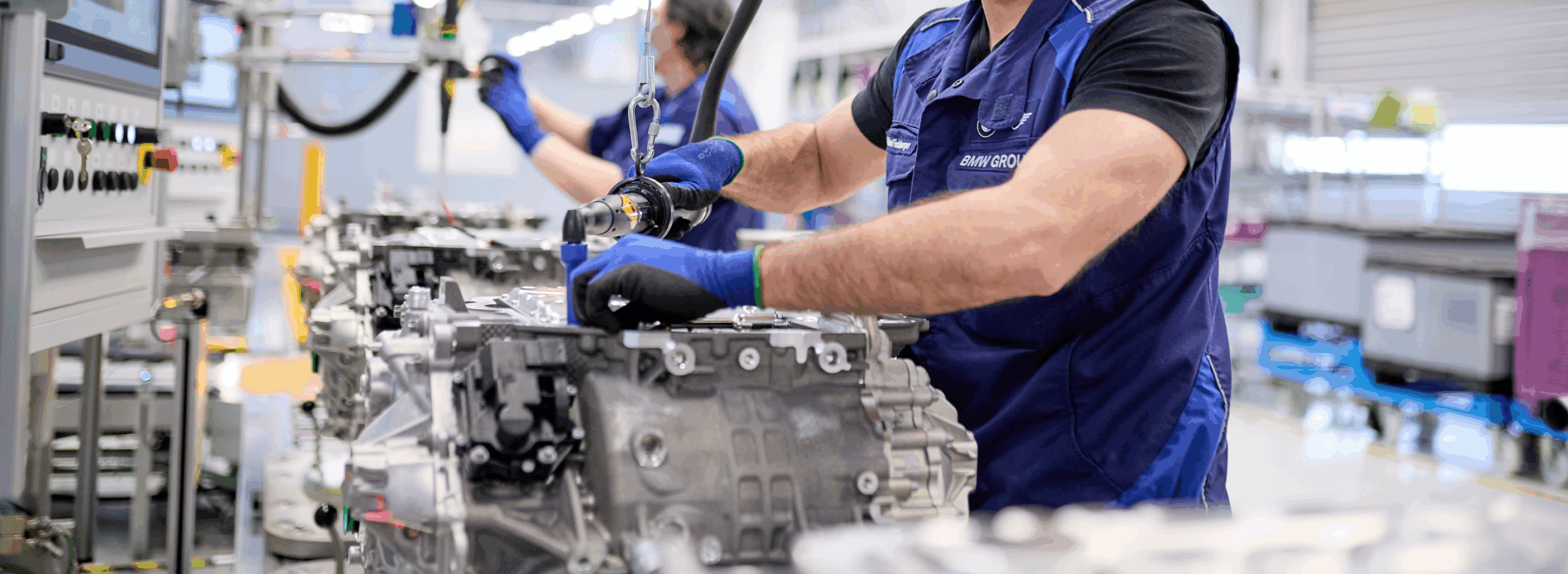

Tech that works every shift

Reduce downtime, simplify retrofits, and make automation less of a headache.

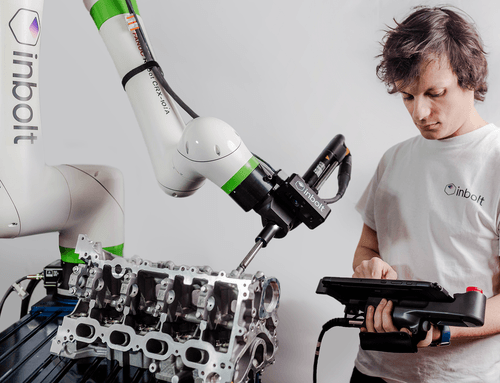

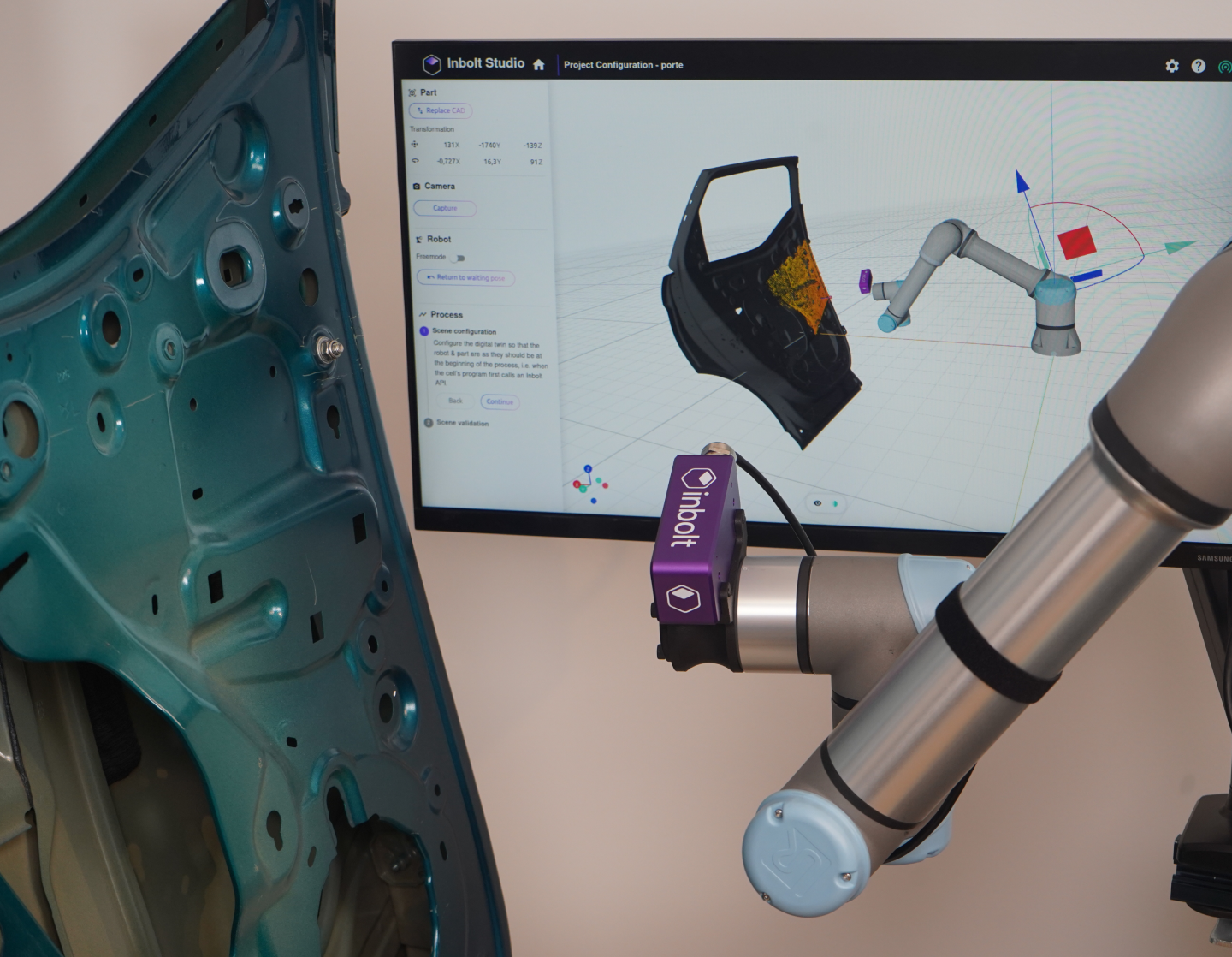

Fast and simple setup

Install Inbolt on existing robots in hours and train from a CAD model. No complicated programming or costly fixture redesign.

Less firefighting

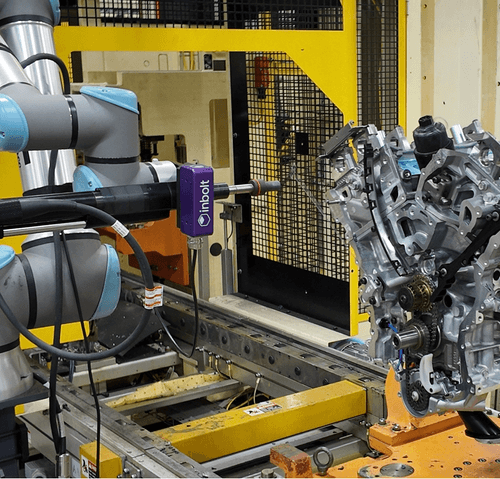

Our AI adapts to part shifts, misalignments, and lighting changes in real time so you spend less time troubleshooting and more time improving output.

Keep production moving

Avoid unplanned stops and collisions with live trajectory updates that keep robots working through variability without slowing cycle times.

Explore more from Inbolt

Access articles, use cases, and resources to see how Inbolt drives intelligent automation worldwide.

Albane Dersy named one of “10 women shaping the future of robotics in 2025”

The Rise of Vision-Based Robotics in Automotive Manufacturing

Stellantis Reduces Tightening Rejects by 91% with Inbolt’s Vision-Guidance at their Trenton Plant

iREX 2025 (Dec 3-6)

Built for the factory floor

Every feature is designed to make engineers’ lives easier and stations more reliable.

Robot-mounted vision

One camera per robot delivers better accuracy and flexibility without extra infrastructure.

Lighting agnostic

Works in the real-world factory environment without special lighting or setups.

Real-time updates

Continuously recalculates robot paths to prevent stops and keep OEE high.

Engineers, let’s fix your line

Speak with our team about retrofitting your robots and simplifying your workflows. We will help you deploy quickly, cut downtime, and boost production efficiency.