Why managers choose Inbolt

Faster deployment, clear ROI, and scalable automation that works in real-world conditions.

Fast, proven ROI

Achieve payback in as little as three months thanks to faster commissioning, reduced downtime, and fewer production errors.

Scalable across sites

Deploy Inbolt on multiple lines and facilities with a repeatable setup process and hardware-agnostic integration.

Future-ready automation

Adopt flexible, software-first robotics guidance that grows with your production needs and adapts to future part variants.

Proven results in real factories

Explore more from Inbolt

Access articles, use cases, and resources to see how Inbolt drives intelligent automation worldwide.

KUKA robots just got eyes: Inbolt integration is here

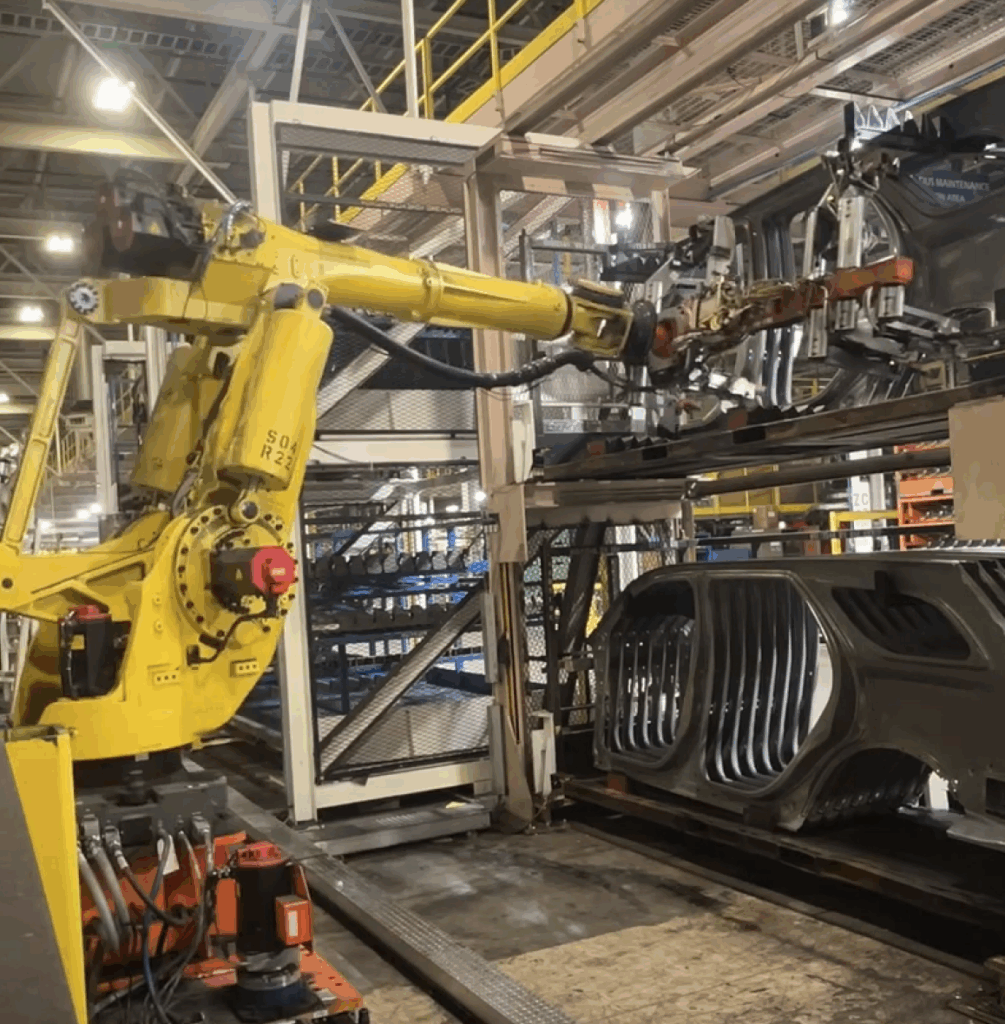

Stellantis Enhances Bodyshop Efficiency by 97% with Inbolt’s Vision-Guided De-Racking Solution

Stellantis Booster Day (Oct 29)

Sifted Podcast: Europe’s AI opportunity – The next few years

Built to meet your business goals

Every feature is designed to maximize uptime, cut costs, and deliver enterprise-scale performance.

Rapid deployment

Train from a CAD model and deploy in days, avoiding lengthy downtime during rollout.

Hardware agnostic

Works with FANUC, ABB, UR, KUKA, and more, fitting seamlessly into existing infrastructure.

Real-world proven

Deployed in 70+ factories and hundreds of robots, delivering measurable impact in production.

Ready to Scale Your Automation?

Talk to our team about retrofitting existing robots or powering new stations. We will help you deliver ROI faster, reduce downtime, and scale automation across your sites.