Proven impact, measurable results

1

< 1 sec

Process time per pick

80

< 80 ms

Perception to motion

70

70 +

Factories using Inbolt

95

95 %

Picking success rate

Smarter bin picking for every factory

Flexible, precise, and affordable. Inbolt makes robots pick and place like humans, but faster.

Human-like adaptability

Unlike rigid overhead-camera systems, Inbolt lets robots grasp parts however they can, then uses in-hand localization to adjust trajectory mid-move. This human-like adaptability boosts success rates and reduces errors.

Flexible & cost-efficient

One robot-mounted camera handles any bin, anywhere, no custom fixtures, no multiple cameras. Compact vision hardware keeps costs down while delivering robust, factory-ready performance at scale.

Proven in plants

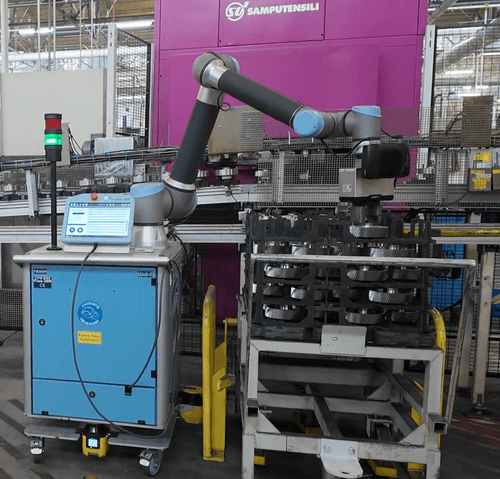

Deployed in major OEM plants, Inbolt automates raw material handling, line loading, and small-part picking with higher throughput and lower downtime across both semi-structured and fully unstructured bins.

Features that redefine bin picking & depalletization

Inbolt combines vision, AI, and human-like adaptability to deliver faster, more flexible bin picking.

Robot-mounted vision

One camera per robot handles any bin size or position, without fixed rigs or multiple cameras.

Human-like grasping

Grasp parts from any pickable side, just like a human. This gives robots more possible grasp points.

In-hand localization

Robots adapt mid-move by analyzing parts in hand and adjusting placement trajectory in real time.

Cost-optimized hardware

Close-range vision allows efficient, affordable cameras without compromising performance or accuracy.

Higher success rates

Adaptive grasping and trajectory adjustment boost pick reliability compared to overhead systems.

Proven in factories

Trusted by major OEMs for raw material handling, body panels, and small-part bin picking.

Proven results in real factories

Flexible bin picking at Caen reduced downtime and sped up production.

Vision-guided bin picking boosted throughput and cut errors at Mirafiori.

FAQ

Answers to common questions about Inbolt’s vision-guided bin picking and depalletization.

-

Unlike traditional overhead-camera systems, Inbolt mounts the vision camera directly on the robot. This approach reduces cost, increases flexibility, and enables robots to handle bins of any size or position. Our in-hand localization technology lets robots adjust their trajectory after grasping a part, ensuring accurate placement even with irregular shapes or orientations. The result is higher picking success rates, fewer errors, and lower overall automation costs.

-

Yes. Inbolt is designed for both semi-structured and fully unstructured bins. Instead of relying on rigid part orientation, the system identifies any graspable side of a part. Once picked, the robot uses in-hand localization to re-analyze the object and adjust its placement in real time. This human-like adaptability allows Inbolt to succeed where other systems fail, making it possible to automate even the most variable bin scenarios.

-

Inbolt requires only a robot-mounted 3D vision camera and our proprietary AI software. Because the camera is positioned close to the parts, it does not need to be expensive or high-resolution, making the setup cost-efficient. Unlike overhead systems that require one camera per bin and rigid positioning, Inbolt needs just one camera per robot—flexible across any bin size or placement.

-

In-hand localization is a core differentiator of Inbolt. Once the robot grasps a part, the camera continues to monitor and analyze it during movement. If orientation or position isn’t perfect, the software recalculates the placement trajectory on the fly. This ensures that every part is placed precisely, significantly reducing errors and rework while boosting throughput. It’s automation that adapts in real time, like a human operator would.

-

Inbolt’s bin picking solution is proven in automotive plants for handling raw materials like disc brakes, steering knuckles, and gears, as well as line loading body panels and small metal sheets. It’s also applicable in electronics, home goods, and general manufacturing where variability in bins makes automation difficult. Our system’s adaptability makes it suitable for a wide range of industrial bin picking and depalletization needs.

-

Manufacturers typically see ROI in 3–6 months depending on the application. By eliminating the need for costly fixtures, reducing placement errors, and accelerating deployment, Inbolt significantly lowers automation costs. Customers also benefit from higher throughput and fewer manual interventions. In one case, Stellantis achieved a 12-month ROI while saving over 2.7 tons of fixture hardware weight daily.

Start your bin picking project

Talk to our team about automating bin picking and depalletization in your factory. We’ll help you deploy fast, boost picking success rates, and reduce integration costs.

Explore more from Inbolt

Access articles, use cases, and resources to see how Inbolt drives intelligent automation worldwide.

Inbolt Bin Picking Datasheet

KUKA robots just got eyes: Inbolt integration is here

FANUC Collaborative Days (Oct 3)

Sifted Podcast: Europe’s AI opportunity – The next few years