Proven impact, measurable results

5

< 5 mins

Training time

80

< 80 ms

Part detection latency

0.5

0.5 mm

Ultra-precise localization

70

70 +

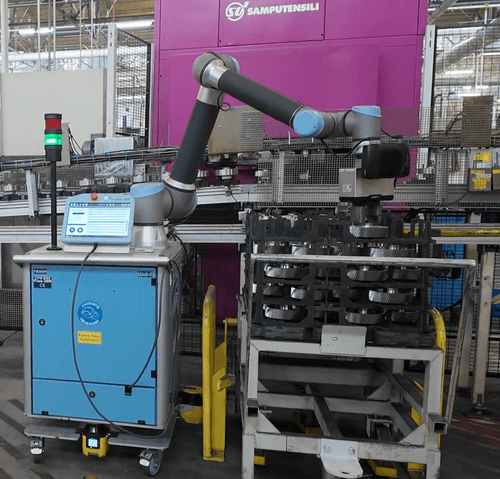

Factories using Inbolt

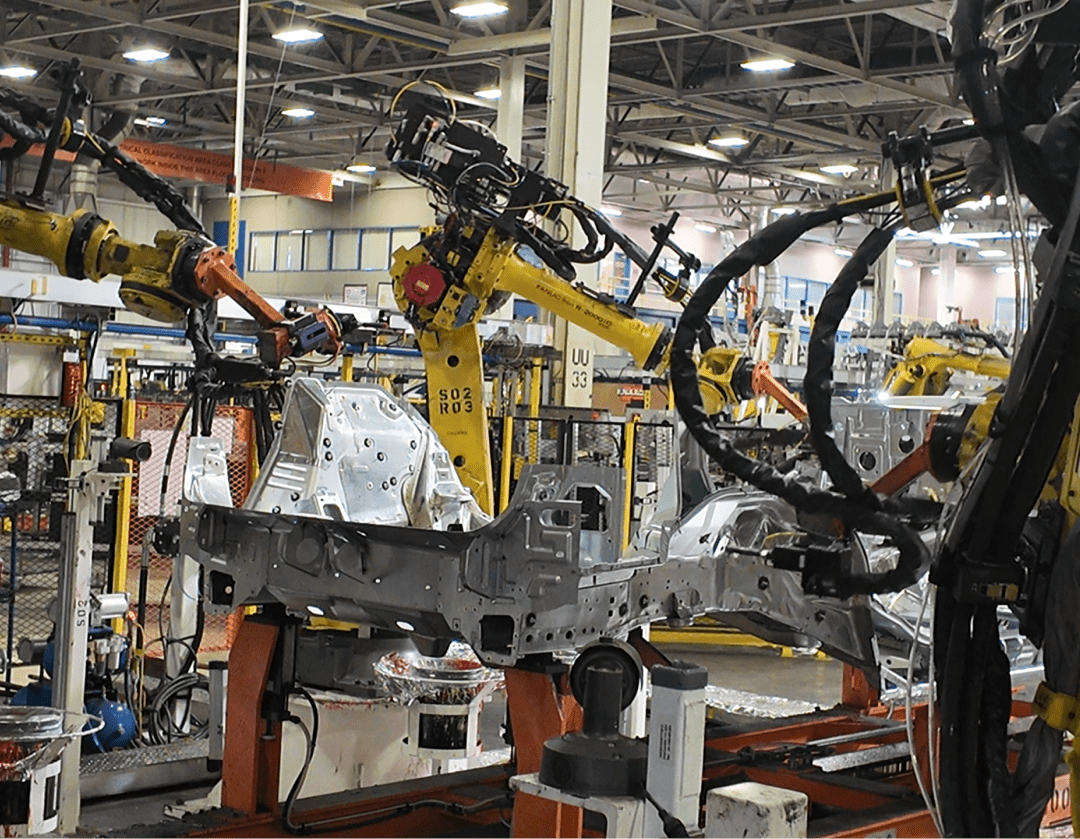

Why manufacturers choose Inbolt for dispensing

Better quality, less waste, and higher productivity in adhesive applications.

Consistent quality

Inbolt ensures uniform bead application with real-time path adjustment, reducing rejects and avoiding costly rework.

Less material waste

Adaptive robot guidance optimizes glue flow and placement, saving material and lowering operating costs.

Faster cycle times

No need for rigid fixtures or perfect part positioning. Robots find and follow paths instantly, keeping production moving.

Technology that keeps dispensing precise

Robot-mounted vision and AI adapt bead paths in real time for perfect results.

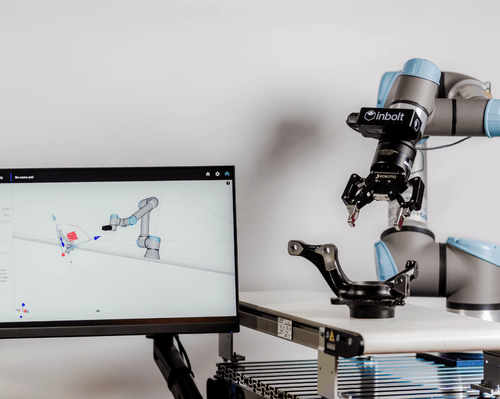

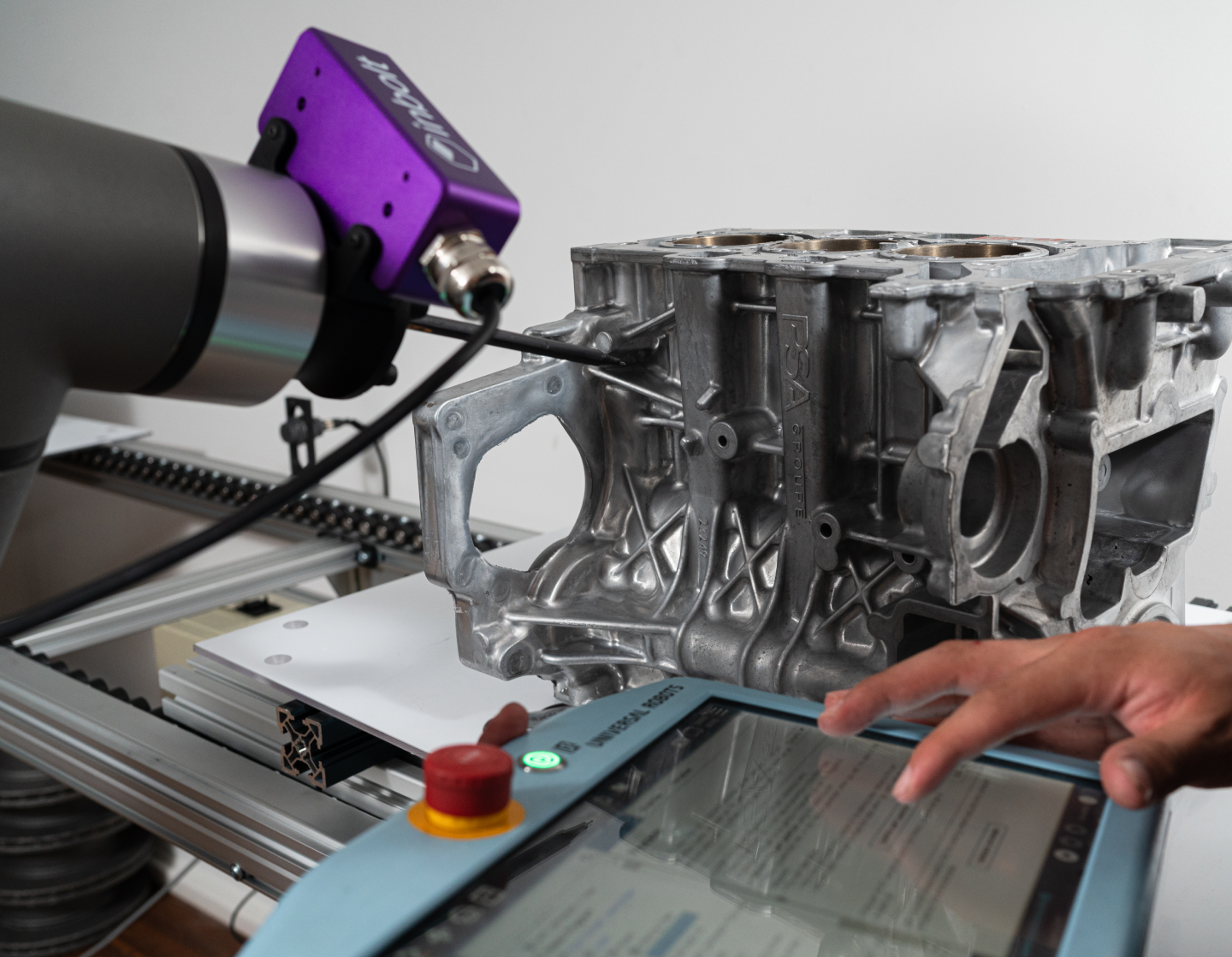

Robot-mounted 3D vision

Guides the robot directly at the point of application for maximum precision and flexibility.

Real-time trajectory updates

Automatically adapts the bead path to misaligned or shifting parts during production.

CAD-based setup

Train the robot from a CAD model to reduce commissioning from weeks to days.

LIghting agnostic

Delivers accurate guidance in any factory lighting conditions with no extra setup.

Edge AI processing

Computes paths in milliseconds without cloud dependency, ensuring reliable uptime.

Integration ready

Compatible with major robot brands for easy deployment across multiple lines.

Proven results in real factories

FAQ

Your top questions about vision-guided glue and mastic dispensing, answered.

-

Yes. Inbolt can be added to existing dispensing robots or new stations. Our robot-mounted camera and AI software integrate with leading robot brands to upgrade precision without major infrastructure changes.

-

Inbolt supports glue, mastic, sealants, and similar adhesives. Its vision system adapts to different bead thicknesses and patterns, ensuring consistent results across a wide range of applications.

-

Yes. Our system adjusts the robot trajectory in real time, following curved, angled, or irregular surfaces with high accuracy, reducing bead gaps and over-application.

-

With CAD-based training and pre-calibrated algorithms, most systems are deployed in days, not weeks, with minimal downtime for your production line.

-

No. Inbolt is lighting agnostic, so you do not need controlled environments or special fixtures to achieve accurate results.

-

Most customers see ROI in 6 months thanks to reduced waste, faster cycle times, and lower rework rates.

Ready for flawless dispensing?

Speak with our team to see how Inbolt can upgrade your dispensing stations for perfect results, higher throughput, and lower material costs.

Explore more from Inbolt

Access articles, use cases, and resources to see how Inbolt drives intelligent automation worldwide.

FANUC Collaborative Days (Oct 3)

Sifted Podcast: Europe’s AI opportunity – The next few years

Inbolt Product Brochure

Sim2Real Gap: Why Machine Learning Hasn’t Solved Robotics Yet