Proven impact, measurable results

91

91 %

Part rejects reduced

5

< 5 mins

Training time

70

70 +

Factories using Inbolt

40

40 M

Robot cycles powered in 2025

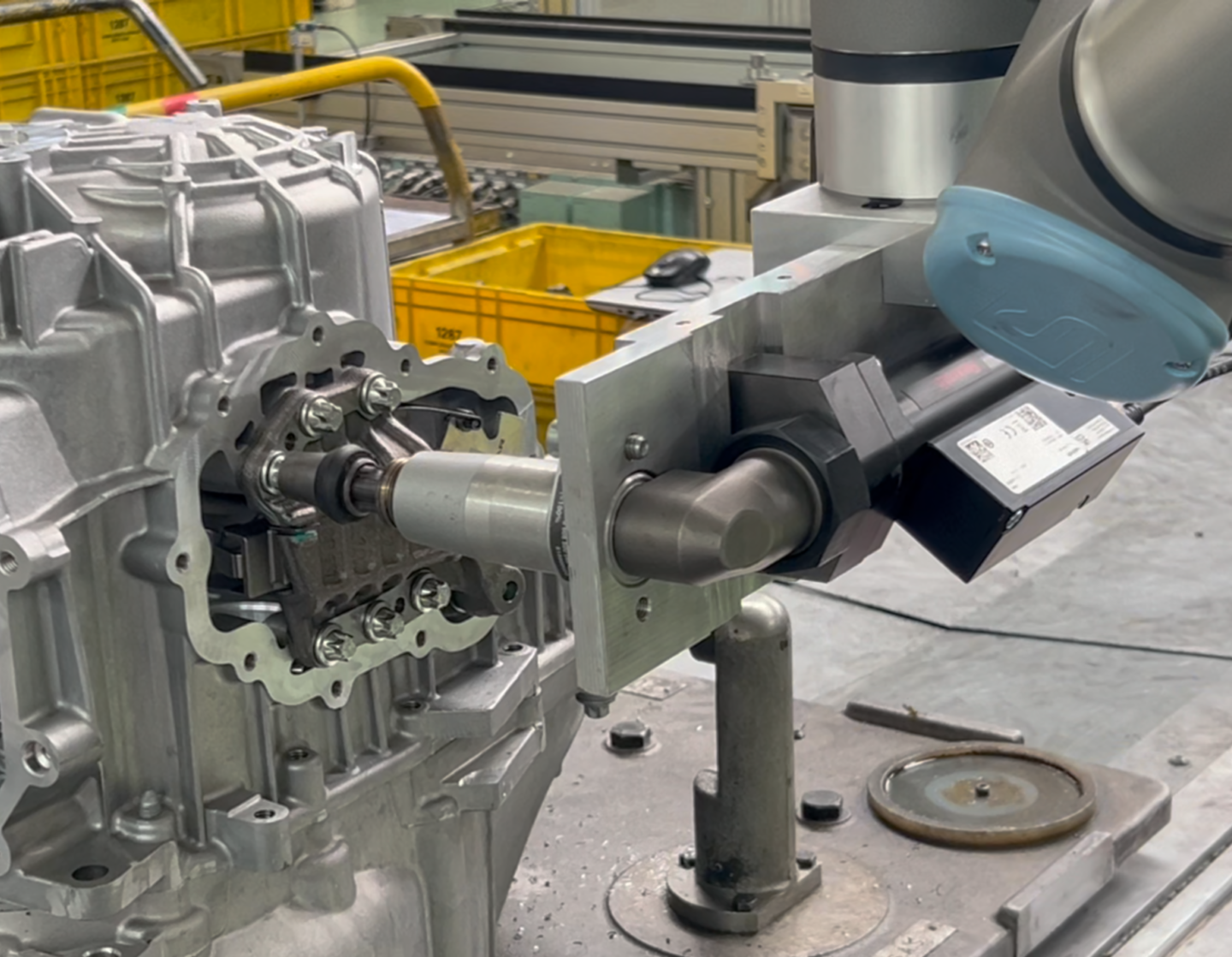

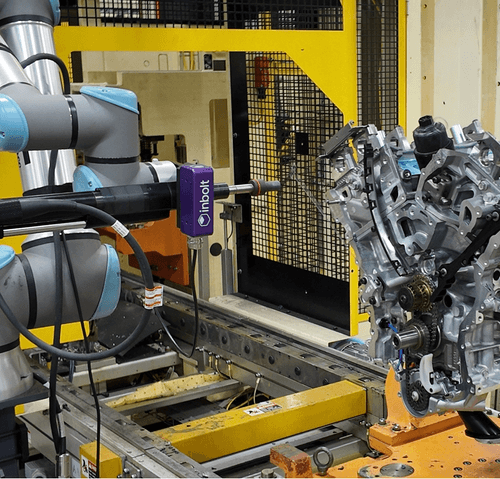

Precision fastening without slowdowns

Better accuracy, fewer rejects, and a smoother production line.

Reduce rejects up to 90%

Our vision-guided robots dynamically compensate for misalignments, drastically cutting bolt tightening failures and rework costs.

No infrastructure changes

Skip the cost and downtime of lift-and-locate systems. Inbolt retrofits seamlessly to existing stations, keeping your line running.

Boost throughput

Minimize tool non-engagements and improve cycle time by keeping robots engaged and accurate on every single fastening task.

Technology built for perfect fastening

Real-time 3D vision and AI guidance for zero-miss screw driving.

Robot-mounted vision

Achieve precise part localization from the robot’s perspective with a single camera per station.

Dynamic adjustment

Handles x, y, z, yaw, pitch, and roll variations automatically to keep tools engaged.

No lift & locate needed

Avoid slow, costly positioning systems by letting vision handle alignment in real time.

CAD-based deployment

Deploy fast by training directly from CAD models, no special fixtures required.

High repeatability

Achieve 10× repeatability for consistent fastening and higher OEE.

Lighting agnostic

Run reliably under real factory conditions without extra lighting setups.

Proven results in real factories

Dynamic line tightening at Verrone cut cycle time and boosted uptime.

FAQ

Answers to the most common screw driving and fastening questions.

-

Yes. Inbolt integrates with existing robots without requiring lift-and-locate systems or major mechanical rework. We retrofit in hours and immediately improve accuracy and throughput.

-

By using real-time part localization and trajectory recalculation, Inbolt ensures the tool engages correctly with each bolt regardless of part movement or position, reducing rejects by over 90%.

-

No. In fact, Inbolt eliminates the need for slow mechanical positioning steps. Our solution typically improves cycle time by 10–30%.

-

Operators can stay focused on exceptions rather than rework. Inbolt reduces manual interventions dramatically, improving ergonomics and productivity.

-

Yes. Our software-first approach makes it easy to scale from one station to many, using the same CAD data and robot integration.

-

Most plants see ROI within 3-6 months thanks to reject reduction, labor savings, and higher throughput.

Ready to eliminate fastening errors?

Let’s talk about retrofitting your screw driving stations. We’ll help you cut rejects, reduce rework, and achieve fast ROI with intelligent robot guidance.

Explore more from Inbolt

Access articles, use cases, and resources to see how Inbolt drives intelligent automation worldwide.

Albane Dersy named one of “10 women shaping the future of robotics in 2025”

American Automotive Summit (Oct 21-22)

The Rise of Vision-Based Robotics in Automotive Manufacturing

Inbolt Joins NVIDIA Inception to Accelerate AI-Driven Automation