Automotive OEM enhances automation performance by leveraging Inbolt’s intelligent vision and organizational capabilities

Customer: Stellantis

Location: Detroit, USA

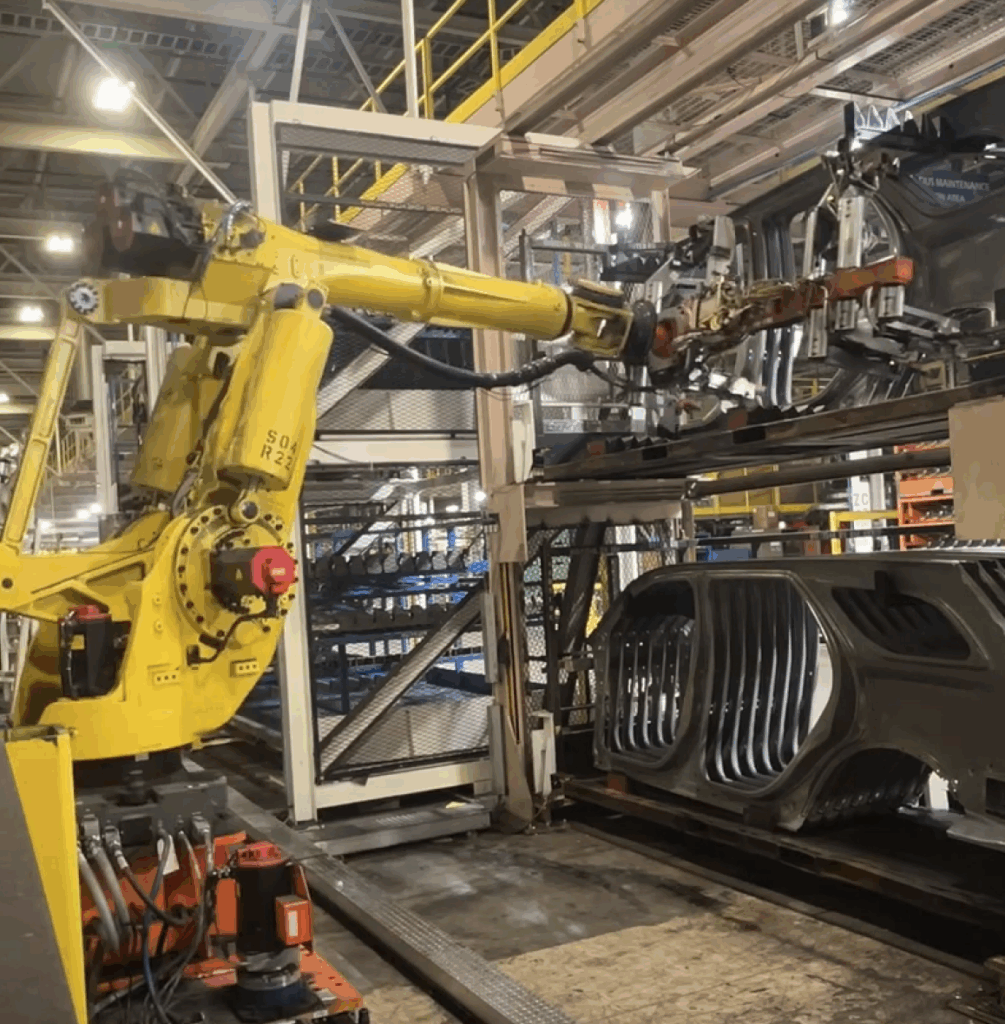

Application: Static de-racking of underbody framing rails

Approach: In-house automation with Inbolt 3D vision

Context

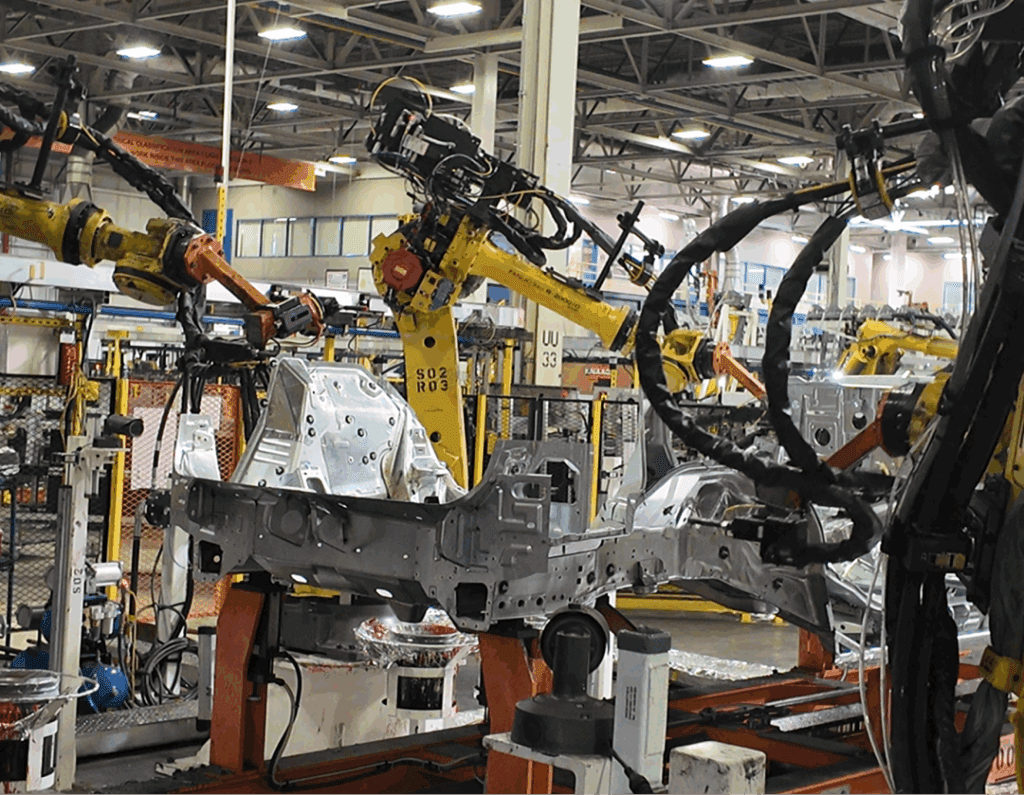

At Stellantis’ Jefferson plant in Detroit, underbody framing rails were traditionally de-racked manually. While some parts on the line were already automated, this specific operation remained operator-dependent.

The mix of parts added complexity with around 70% from an older vehicle model and 30% from a newer one, all handled within the same station. Stellantis’ objective was clear: they wanted to automate the full process without rebuilding the cell, and do so in a way that remained cost-effective and flexible.

An external automation approach was initially assessed. In parallel, Stellantis identified an opportunity to leverage its strong internal engineering expertise to design a solution that would better balance performance, flexibility, and investment levels

The challenge

The team set out to create a fully automated de-racking station built in-house, reusing as much of the existing setup as possible:

- Keep the current line and layout

- Retrofit the robots’ end-of-arm tooling

- Modify racks and create nests with the toolmaker

- Avoid complex fixtures or heavy re-engineering

To support automation across multiple part references, the existing racks were reworked with the toolmaker. Each robot originally handled four racks dedicated to a single part reference ‘WL’, while the ‘WD’ parts were still processed manually. The racks were modified to accommodate a mixed configuration, with two racks for ‘WL’ parts and two for ‘WD’ parts, despite their different geometries. In parallel, dedicated mechanical nests and buffer components were designed and added to ensure stable positioning and repeatable handling of the parts before robot pickup.

A first version of the cell was commissioned without vision. While promising, it reached around 60% picking accuracy, insufficient for reliable production. Without precise, real-time part localization, the system could not consistently detect the exact position of each rail.

To reach production-level reliability, vision became essential.

The solution: adding real-time vision and intelligence

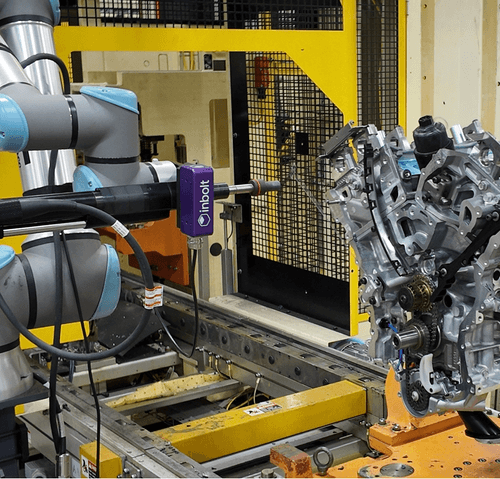

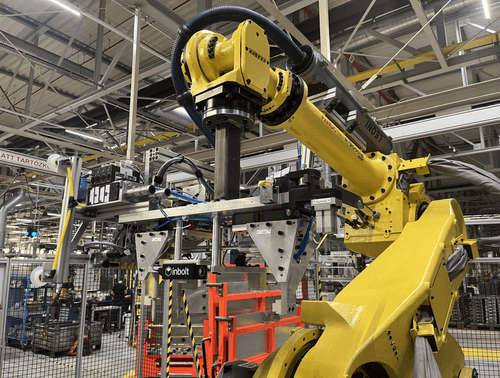

Stellantis invited Inbolt to collaborate directly with the internal team and integrate vision into the station.

Inbolt’s 3D camera was mounted directly on the robot end-of-arm, giving the robot the ability to see the part from its own point of view. With a scanned model of the rail and a well-prepared camera mounting position, the system was deployed rapidly:

- No fine-tuning required

- Precise 3D localization of each part in the rack

Thanks to Inbolt’s real-time vision, the robot could now detect exactly where each rail was and adapt its motion accordingly.

The full robot and vision deployment took just two days, from installation to operational readiness.

Results

With Inbolt integrated, the station reached 100% picking accuracy, unlocking full automation of the de-racking process.

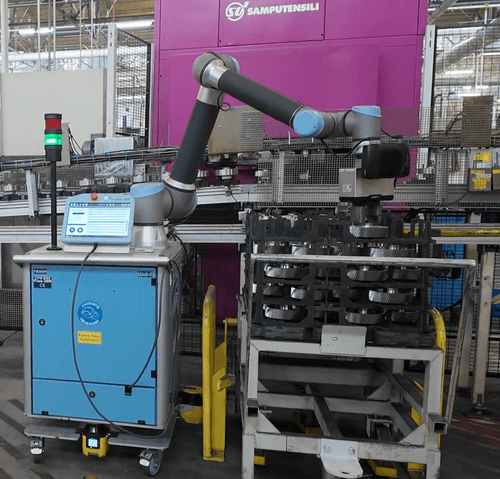

In addition to technical performance, the project delivered a strong economic return:

- Validated an in-house & Inbolt hybrid model for automation

- A significantly lower overall investment compared to traditional turnkey approaches

- Achieved production-grade accuracy while significantly reducing costs

- Created a reference project for other plant managers

Inbolt was already trusted on 10 robots in the same plant, which made it a natural partner for this initiative. This project marked the first fully new station co-created from scratch with Stellantis at the Jefferson site, setting a strong foundation for future deployments. Stellantis achieved production-grade automation while reducing automation costs by an order of magnitude, accelerating ROI and maintaining full control over the station design.

Why it matters

This project shows how manufacturers can:

- Reuse existing cells instead of rebuilding from scratch

- Combine internal know-how with Inbolt’s real-time vision intelligence

- Achieve faster deployment, lower CAPEX, and strong ROI

- Create automation strategies that scale across plants

By giving robots the ability to see and adapt in real time, Inbolt helped Stellantis remove a key bottleneck, turning a previously manual, variable operation into a robust, fully automated, and cost-efficient production station.

Explore more from Inbolt

Access similar articles, use cases, and resources to see how Inbolt drives intelligent automation worldwide.

70% improvement in cycle efficiency for glue dispensing

30% Cycle Time Reduction in Automotive Pick & Place

Stellantis Reduces Tightening Rejects by 91% with Inbolt’s Vision-Guidance at their Trenton Plant

Stellantis Valenciennes Cuts 2.7 Tons in Daily Handling with Inbolt’s Vision-Guided Automation

Stellantis Enhances Bodyshop Efficiency by 97% with Inbolt’s Vision-Guided De-Racking Solution

Stellantis automates semi-structured depalletizing with Inbolt

Stellantis Automates Small Parts Pick and Place