Proven impact, measurable results

5

< 5 mins

Training time

80

< 80 ms

Perception to motion

0.5

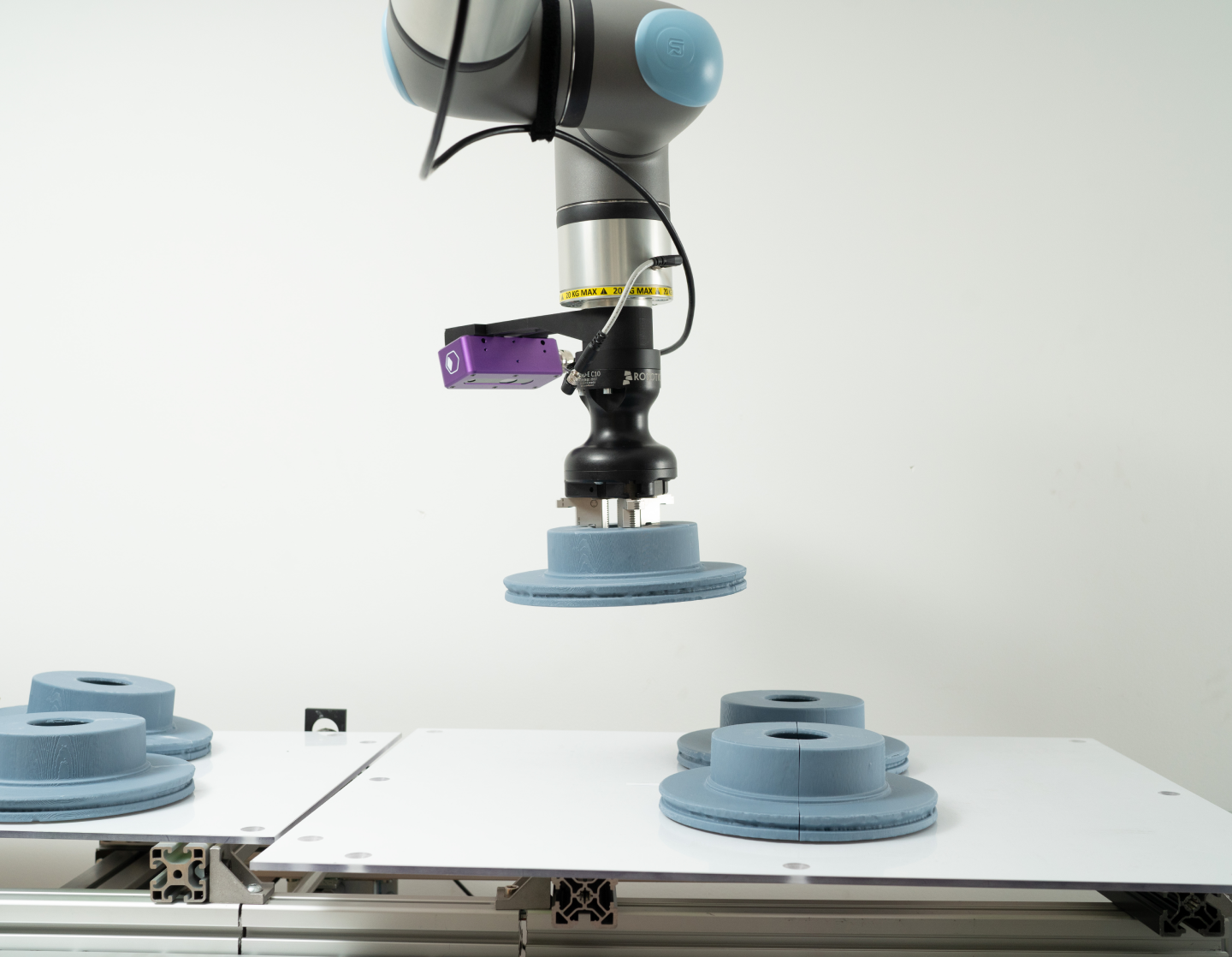

0.5 mm

Ultra-precise localization.

70

70 +

Factories using Inbolt

Why choose Inbolt vision-guidance

Reduce costs, speed commissioning, and make automation resilient with real-time vision-guided intelligence.

Lower automation costs

Eliminate the expense of custom jigs and fixtures. Inbolt’s vision-guided robotics reduces setup costs and simplifies integration, making automation more affordable.

Greater flexibility

Adapt quickly to new parts, models, or processes without redesigning tooling. One system handles variability, enabling flexible, future-proof automation.

Faster commissioning

Deploy in days, not weeks. With real-time part localization and simplified setup, Inbolt minimizes engineering time and accelerates production start-up.

Proven performance

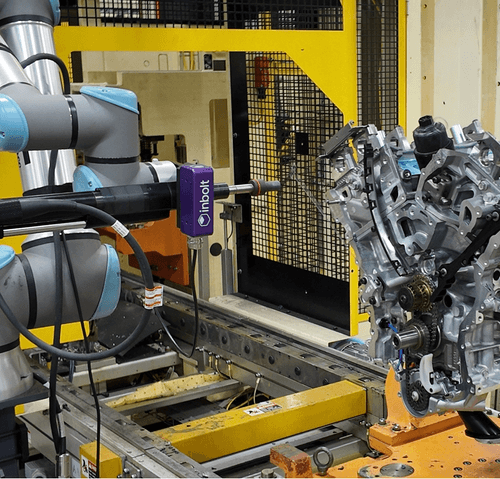

Deployed in +70 plants and trusted by leaders like Volkswagen, Ford, and Toyota, Inbolt delivers reliable automation in unpredictable, real-world production environments.

Engineered for real-world production

From CAD-trained AI to robust hardware, Inbolt ensures consistent accuracy and adaptability across diverse production setups.

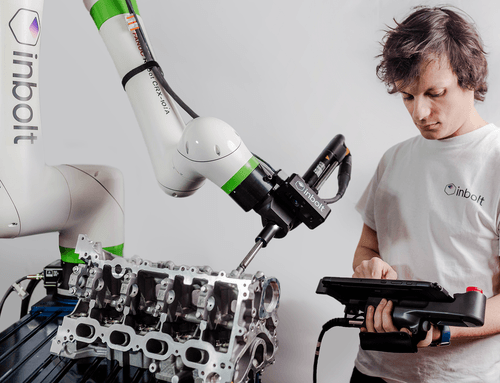

Real-time AI localization

Detects and locates parts instantly in production, using CAD-trained AI models to deliver precise and reliable robot guidance.

Fast deployment

Install and deploy on-premise in under 10 minutes with a user-friendly interface.

Robot-mounted 3D camera

Mounted directly on the robot for maximum flexibility, with standard and high-precision options to match your application needs.

Unmatched reliability

Achieves near-100% part detection rates in runtime, ensuring maximum uptime.

Hardware agnostic

Compatible with major robot brands and flexible with camera input for any setup.

Lighting independent

Performs consistently even in low-light or changing factory environments.

FAQ

Answers to the most common questions about Inbolt vision-guidance for robots, from deployment speed to compatibility and ROI.

-

Inbolt vision-guidance gives robots the ability to see and adapt in real time. Unlike traditional automation that relies on rigid jigs or fixtures, Inbolt uses robot-mounted 3D cameras and AI-powered part localization to detect part positions and orientations directly on the factory floor. This means robots can handle variability, misalignments, and moving lines without costly engineering changes. The result is smarter robots, faster commissioning, and automation that works reliably in unpredictable manufacturing environments.

-

One of Inbolt’s biggest advantages is deployment speed. Thanks to CAD-trained AI and intuitive setup, most projects can be commissioned in days, not weeks. On-site installation typically takes less than 24 hours, and new parts can be added in under 10 minutes without complex reprogramming. This makes Inbolt the fastest way to retrofit existing robots or power new stations, reducing downtime and accelerating ROI.

-

Inbolt is hardware agnostic and integrates with leading robot brands including FANUC, ABB, Universal Robots, Yaskawa and KUKA. The system is designed to connect seamlessly with both stationary and moving-line applications. Even if your robots aren’t listed, our engineering team can evaluate compatibility and provide integration support. This flexibility makes Inbolt a future-proof choice for manufacturers with diverse fleets of robots.

-

Traditional automation often requires custom jigs, fixtures, or precise part positioning systems, which are expensive and time-consuming to maintain. Inbolt eliminates these costs by using real-time vision-guidance, allowing robots to adapt directly to part variability and placement errors. This reduces capital expenses on hardware and lowers ongoing maintenance costs. Manufacturers deploying Inbolt report significantly lower setup costs, faster ROI, and less rework compared to legacy automation methods.

-

Yes. In fact, Inbolt is the only vision-guidance system that enables reliable real-time part detection and robot guidance on continuously moving lines. This is a game-changer for industries like automotive and electronics, where conveyors are standard. Inbolt’s AI processes 3D inputs in milliseconds, allowing robots to track and adapt their movements on the fly, even when parts are in motion. This makes true lights-out automation possible across more environments than ever before.

-

Inbolt delivers some of the fastest ROI in industrial automation. Customers like Stellantis, Ford, and Beko have seen returns in as little as 3–6 months. By reducing downtime, eliminating costly fixtures, cutting reject rates, and speeding up commissioning, Inbolt helps manufacturers lower costs and increase output simultaneously. Every deployment is backed by real-world proof. Inbolt is already trusted in over 50 factories worldwide.

Let’s talk vision-guided automation

From misaligned parts to moving lines, Inbolt helps robots handle real-world challenges. Fast to deploy, easy to scale, and trusted by leading manufacturers. Contact us to learn more.

Explore more from Inbolt

Access articles, use cases, and resources to see how Inbolt drives intelligent automation worldwide.

Reliable 3D Tracking in Any Lighting Condition

Inbolt Product Brochure

Albane Dersy named one of “10 women shaping the future of robotics in 2025”

Inbolt and FANUC Pioneer Robots that Think and Act on the Fly at Moving Assembly Line Speeds