Blog

Explore insights from the frontlines of vision-guided robotics. Read about market trends, automation strategies, and how Inbolt is shaping the future of AI-powered manufacturing.

Reliable 3D Tracking in Any Lighting Condition

Lighting is one of the biggest obstacles for traditional 3D vision systems. In real factories,…

The Circular Factory – How Physical AI Is Enabling Sustainable Manufacturing

From concept to reality, circular manufacturing should take center stage. Across the manufacturing world, sustainability…

NVIDIA & UR join forces with Inbolt for intelligent automation

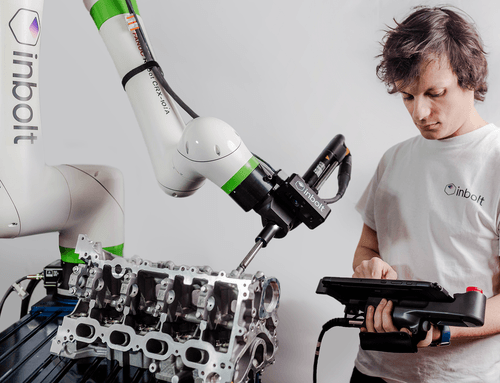

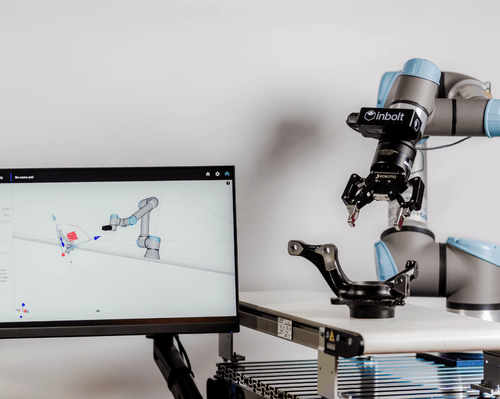

Bridging the gap between humans and robots: Inbolt, Universal Robots, and NVIDIA bring vision to…

KUKA robots just got eyes: Inbolt integration is here

For decades, KUKA robots have been a symbol of strength and precision on factory floors…

Albane Dersy named one of “10 women shaping the future of robotics in 2025”

The International Federation of Robotics has recognized Albane Dersy, co-founder and COO of Inbolt, as…

Want to Sound Smart About Vision‑Guidance for Robots?

Whether you’re new to the topic or looking to deepen your knowledge, here are 11…

Inbolt Joins NVIDIA Inception to Accelerate AI-Driven Automation

Inbolt joins the NVIDIA Inception program to boost its AI-driven automation solutions. This partnership provides…

Inbolt x UR AI Accelerator: Ushering in the Era of Vision-Guided Robotics by Default

Inbolt’s AI-powered software is now integrated into the NVIDIA-powered Universal Robots AI Accelerator Kit, offering…

Inbolt and FANUC Pioneer Robots that Think and Act on the Fly at Moving Assembly Line Speeds

Inbolt and FANUC are launching a manufacturing breakthrough enabling FANUC robots to tackle one of…

Sim2Real Gap: Why Machine Learning Hasn’t Solved Robotics Yet

The most successful areas of application for deep learning so far have been Computer Vision…

Stay updated

Be the first to hear about Inbolt’s latest product updates, case studies, and industry insights. Sign up for our newsletter and never miss a beat on the future of automation.