Expanding GuideNOW’s capabilities

Since the release of GuideNOW, Inbolt’s focus has always been on solidifying the foundations of the product and expanding its capabilities it in order to provide a generalist product for all types of production environment: dynamic, static, small parts, and big parts.

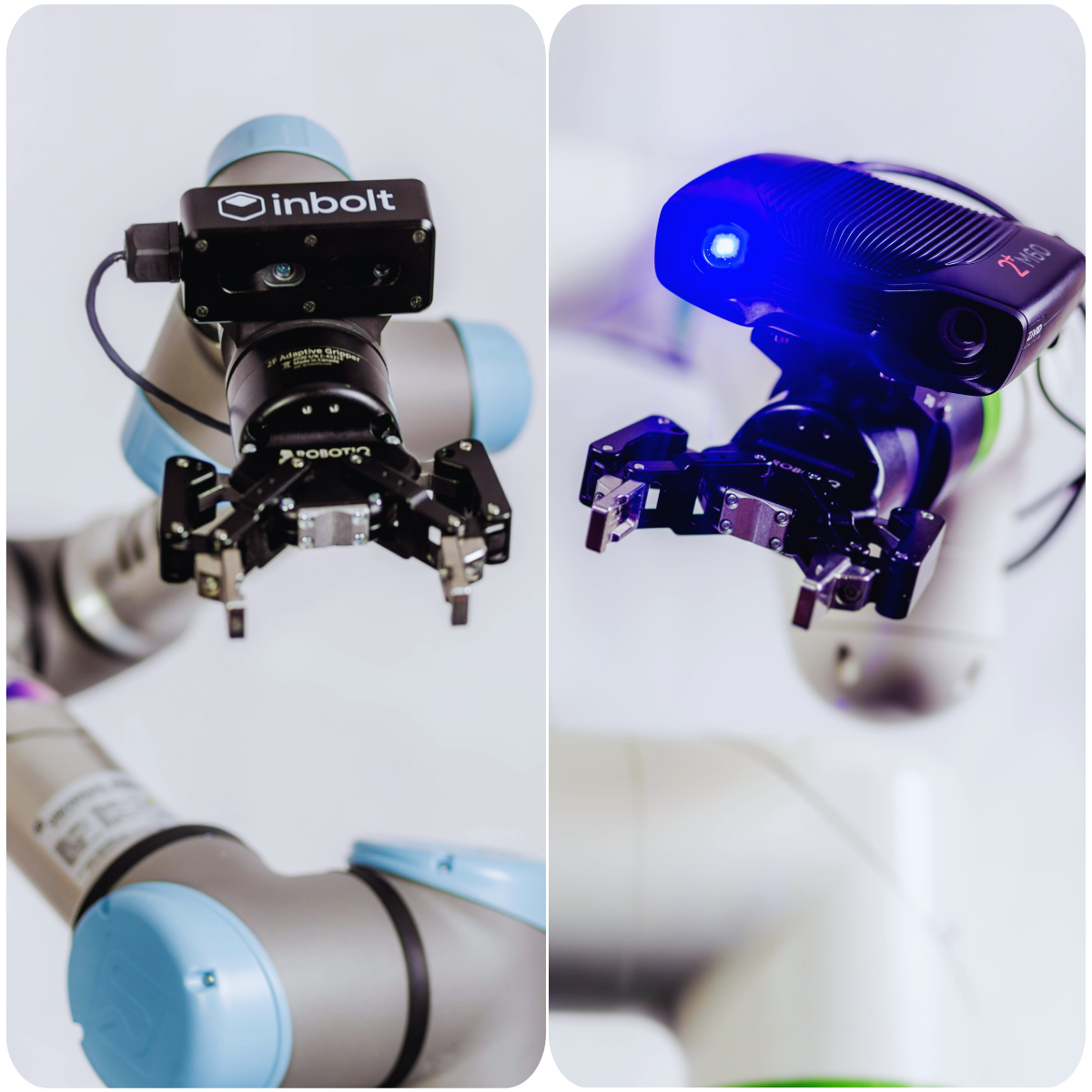

The first camera Inbolt used is the Intel, and the second one we are now adding to our portfolio is the Zivid 2+ M60 camera by Zivid.

This is a strategic decision designed to enhance the system’s capability to handle a wide range of parts geometry with varying requirements for speed and precision.

The GuideNOW system is now compatible with each camera, each for different applications expanding our product portfolio into the GuideNOW Real-time and GuideNOW High-Precision.

In order to facilitate the understanding of which GuideNOW for which use, here’s a practical guide.

GuideNOW Real-time:

⇒ High-speed imaging for dynamic applications. The Intel camera can capture up to 90 frames per second, making it an ideal contestant for applications requiring rapid image capture.

⇒ For bigger parts only. The camera, while fast, produce images with significant noise, especially when imaging objects smaller than 10cm. This noise level can obscure small details, making it challenging to achieve accurate and stable localization for tiny parts.

GuideNOW High Precision:

⇒ High-quality imaging to work on small parts. The camera generates images with much less noise and higher resolution, offering more points per cm². This capability is crucial for accurately capturing and analyzing the details of small objects to ensure precise location identification.

⇒ Static environments only. However capture images at a slower rate. Live tracking is harder to support because of their slower frame capture rate, but GuideNOW High-Precision excels in static processes where high-detail recognition is necessary.

By leveraging both types of cameras and our software-driven capability, the GuideNOW system can now cater to a broader spectrum of industrial tasks.

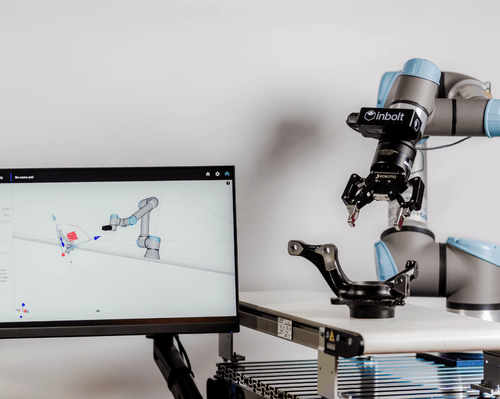

GuideNOW’s AI-powered system can process huge data volumes from these cameras efficiently, at a very fast rate, making it possible for GuideNOW to achieve real-time robot guidance. This is done by matching sensor data with CAD models or 3D scans, particularly beneficial for adaptive and flexible automation.

GuideNOW Performance chart

The combination of Intel RealSense and Zivid cameras allows Inbolt to offer solutions across different environments and tasks—from rapid-moving lines needing quick data capture, to fixed stations/static applications requiring detailed analysis and positioning for other manufacturing tasks. These integrations ensure that Inbolt can offer versatile, precise, and efficient automation solutions, accommodating a most industrial applications and enhancing the overall productivity of robotic guidance systems.

Explore more from Inbolt

Access similar articles, use cases, and resources to see how Inbolt drives intelligent automation worldwide.

NVIDIA & UR join forces with Inbolt for intelligent automation

KUKA robots just got eyes: Inbolt integration is here

Albane Dersy named one of “10 women shaping the future of robotics in 2025”

Want to Sound Smart About Vision‑Guidance for Robots?

Inbolt Joins NVIDIA Inception to Accelerate AI-Driven Automation

Inbolt x UR AI Accelerator: Ushering in the Era of Vision-Guided Robotics by Default

Inbolt and FANUC Pioneer Robots that Think and Act on the Fly at Moving Assembly Line Speeds