Industrial robot cost decline

Industrial robot costs have significantly declined due to technological advancements, increased competition, and open-source development. This has made automation more accessible to various industries, transforming global supply chains and operations.

The decline in industrial robot costs: driving factors and impacts

Over the past few decades, industrial robots have become increasingly accessible as their costs have steadily declined. The global average cost of industrial robots dropped from $46,000 in 2010 to $27,000 in 2017, with projections indicating a further decline to $10,856 by 2025.

This cost reduction has played a significant role in enabling more industries to adopt automation, expanding beyond large-scale manufacturing to smaller businesses and varied sectors like logistics and healthcare. The combination of technological advancements, economies of scale, and increased competition has driven this downward trend.

1. Technological advancements

The evolution of robotics technology is one of the most significant contributors to the reduction in costs. Advances in AI and machine learning have enabled robots to optimize production lines in real-time, while simultaneously driving down their price.

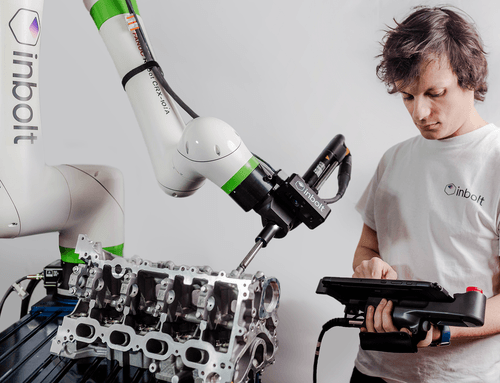

The advent of cobots has also introduced a new generation of robots that are not only more affordable but also more flexible and easier to deploy. Cobots typically have lower initial costs and require less specialized knowledge to set up and operate, reducing the overall expenses associated with automation.

2. Increased competition and open source development

The industrial robotics market has become increasingly competitive, with more manufacturers entering the field and driving innovation. New players are developing low-cost robotics solutions that can compete with established brands, putting downward pressure on prices. In addition, open-source hardware and software platforms have emerged in recent years, allowing smaller companies and research institutions to develop and customize their robots at a lower cost.

For example, the development of ROS (Robot Operating System), an open-source framework for robotics, has provided companies with a foundation to build and customize their robots without needing to invest heavily in proprietary software development. This has significantly lowered the entry barriers for companies looking to deploy robotic solutions.

3. Impact on industries and global supply chains

One of the most visible impacts of the decline has been the democratization of automation technology.

While robotics was once the domain of large automotive and electronics manufacturers, today, various industries are increasingly adopting robotic solutions.

Additionally, the ongoing cost reductions have accelerated the adoption of robots in logistics and warehousing. E-commerce companies, in particular, have benefited from the ability to automate their fulfillment centers with affordable robotic systems, reducing labor costs and improving efficiency.

Conclusion

The drop in industrial robot costs is transforming industries by making automation more accessible, even for smaller businesses. Advances in technology, open-source tools, and increased competition have all contributed to this shift. As costs continue to decline, the adoption of robotics will only grow, streamlining operations and reshaping supply chains across the global economy. The future of automation promises smarter, more efficient manufacturing on a broader scale.

Explore more from Inbolt

Access similar articles, use cases, and resources to see how Inbolt drives intelligent automation worldwide.

Reliable 3D Tracking in Any Lighting Condition

The Circular Factory - How Physical AI Is Enabling Sustainable Manufacturing

NVIDIA & UR join forces with Inbolt for intelligent automation

KUKA robots just got eyes: Inbolt integration is here

Albane Dersy named one of “10 women shaping the future of robotics in 2025”

Want to Sound Smart About Vision‑Guidance for Robots?

Inbolt Joins NVIDIA Inception to Accelerate AI-Driven Automation