Explore Inbolt’s knowledge hub

Dive into our collection of resources designed to help you master vision-guided robotics. Explore ebooks, brochures, case studies, blog articles, and upcoming events – everything you need to learn how Inbolt transforms automation and boosts factory performance.

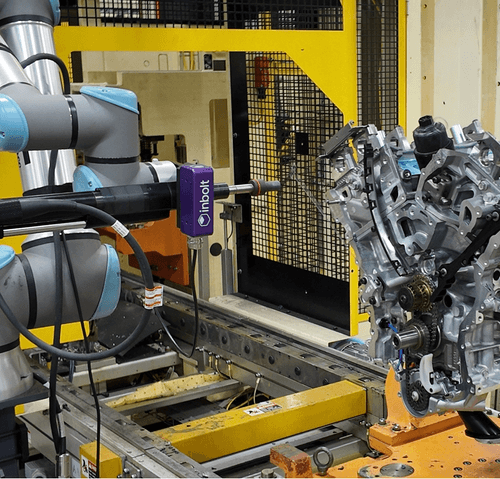

Why the future of automation is being written by the automotive industry

Automotive manufacturing has become the world’s most demanding proving ground for industrial automation. The scale,…

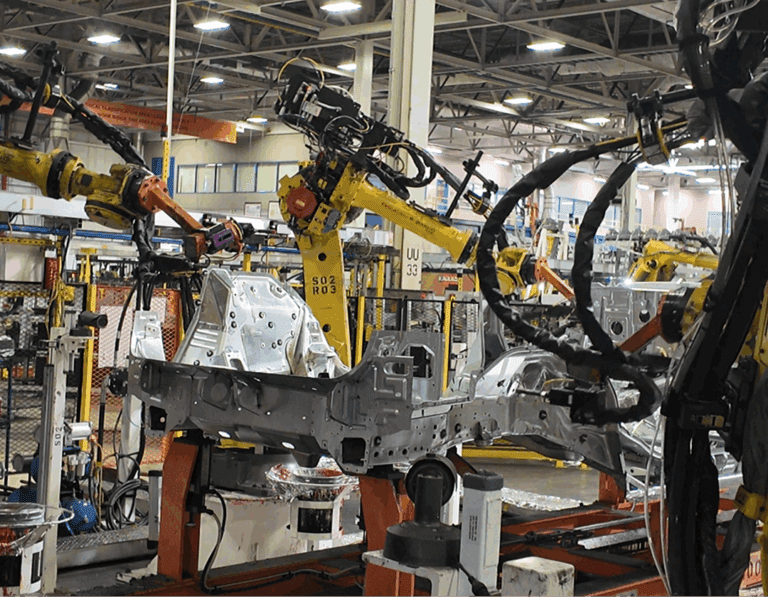

Automotive OEM enhances automation performance by leveraging Inbolt’s intelligent vision and organizational capabilities

Customer: Stellantis Location: Detroit, USA Application: Static de-racking of underbody framing rails Approach: In-house automation…

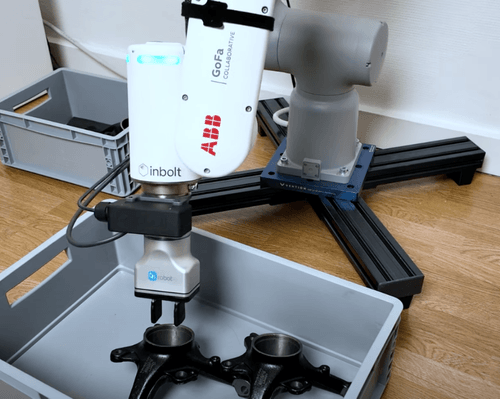

Inbolt Unveils Human-Like Bin Picking Solution Powered by On-Arm AI Vision

The new real-time robot guidance system enables flexible and low-cost bin picking for unstructured environments,…

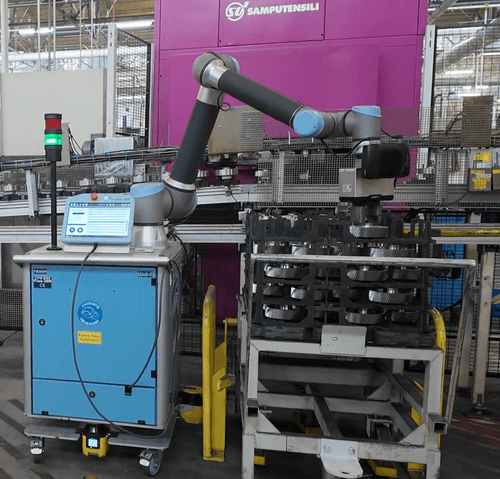

Reliable 3D Tracking in Any Lighting Condition

Lighting is one of the biggest obstacles for traditional 3D vision systems. In real factories,…

Webinar: How Stellantis Uses AI to Boost Robotics Automation from Stamping to Final Assembly

Webinar | Tues 9 Dec | 16:30 PM CET / 10:30 AM EST | 45…

Inbolt Bin Picking Datasheet

Discover how intelligent 3D vision is reshaping bin picking in modern manufacturing. This datasheet…

Inbolt Joins the French Tech 2030 Program, Shaping the Future of European Industry

We are proud to announce that Inbolt has been selected as one of the 80…

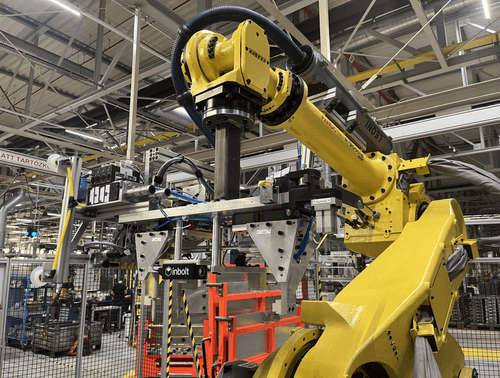

70% improvement in cycle efficiency for glue dispensing

At Stellantis’ Detroit Assembly Complex – Jefferson, Inbolt’s AI-powered 3D vision guidance system enabled precise…

Manufacturing & Production Engineering Magazine: Interview with Albane Dersy

Manufacturing & Production Engineering Magazine interviewed Albane Dersy about the status of computer vision in…

Inbolt Use Case Video Library

Confidential — Internal Use OnlyThis page and its contents are strictly reserved for Inbolt employees…