Proven impact, measurable results

241

241 mm/s

Continuous line speed

80

< 80 ms

Part detection latency

0.5

0.5 mm

Ultra-precise localization

70

70 +

Factories using Inbolt

Why automate moving lines with Inbolt

Cut downtime, boost throughput, and automate jobs once thought impossible — without stopping production.

Continuous production, zero stops

Keep your lines running at full speed while robots work with precision. Inbolt dynamically guides robots in real time so there’s no need to halt production for positioning or reindexing.

Faster ROI, lower costs

No costly mechanical rework or complex fixtures required. Get faster deployment, lower integration costs, and a payback period as fast as three months.

Higher uptime, fewer errors

Eliminate costly collisions, rejects, and rework. Inbolt updates robot trajectories live, ensuring accuracy even with part variability or misalignment.

Built for speed, accuracy, and real-world conditions

From high-frequency control loops to lighting-agnostic vision, Inbolt is designed to keep up with any line.

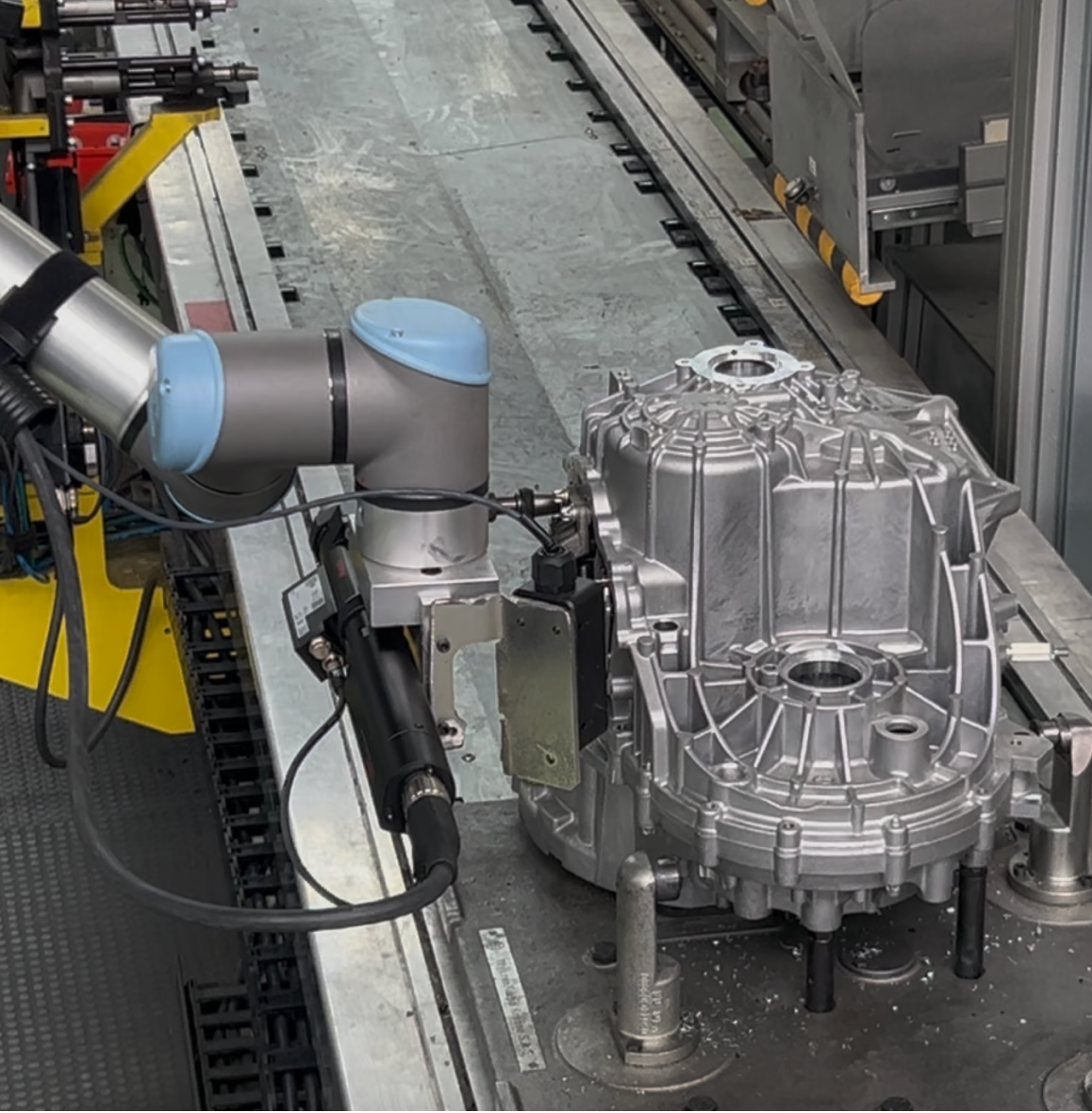

Real-time robot control

High-frequency trajectory updates keep robots synchronized with parts moving at up to 241 mm/sec.

Lighting independent vision

Performs reliably in variable factory lighting, no fixed setup or extra equipment needed.

CAD-based training

Start from a CAD model, not hours of dataset building. Get a new job running in minutes.

Proven results in real factories

FAQ

Your top questions about automating moving lines with Inbolt, answered.

-

No. Inbolt was built to work with continuously moving lines. Our vision model constantly updates the robot’s trajectory so it can adapt on the fly. That means no stop-and-go stations or costly retrofits.

-

Quite the opposite. Inbolt keeps robots moving at line speed, improving cycle times by eliminating search motions, manual intervention, and station stoppages.

-

Inbolt offers localization precision as tight as 0.5 mm with our high-precision camera option. This ensures even critical operations like screwdriving or dispensing stay within spec on a moving line.

-

Inbolt integrates seamlessly with leading brands including FANUC, Universal Robots, ABB, Yaskawa and KUKA. If you use a different robot, contact us — we’re adding compatibility fast.

Let’s keep your line moving

Talk to our team about automating your continuously moving lines with real-time robot guidance. Book a demo or plan your project today.

Explore more from Inbolt

Access articles, use cases, and resources to see how Inbolt drives intelligent automation worldwide.

Albane Dersy named one of “10 women shaping the future of robotics in 2025”

Inbolt Product Brochure

iREX 2025 (Dec 3-6)

Assembly Mag: New Technology Enables Robots to Process Moving Parts

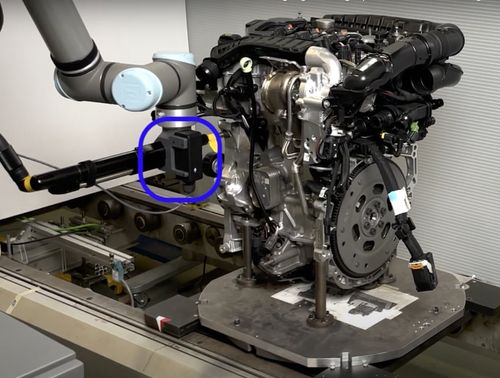

Stellantis Automates Tightening on Moving Lines